40 cheese making process diagram

PRODUCTION OF MOZZARELLA CHEESE. Standard process for cheese making. By "pasta filata" is intended a dairy technique characterised by a double process: the cheese-making in itself, that implies the various phases of coagulation, cutting, draining, shaping, salting and ripening (when necessary); 20. 21. Packaging. - blocks put into plastic bags, vacuum sealed and put. into boxes. - Dry-salt cheese passes through a rapid cool room (~. 24 hours) - Metal detector, coding, then pa ...

A process of manufacturing a mozzarella (or mozzarella-like) cheese comprising the steps of a) pasteurizing cow's milk; b) acidifying the milk to convert it to a cheese milk; c) coagulating the cheese milk to obtain a coagulum comprised of curd and whey; d) cutting the coagulum and draining the whey therefrom, thereby leaving a cheese curd; e) heating, kneading, and stretching the cheese curd ...

Cheese making process diagram

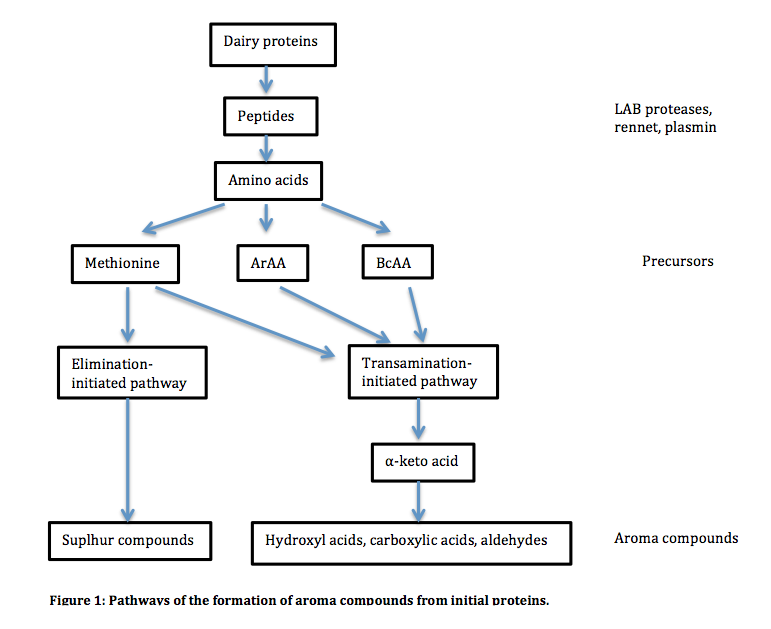

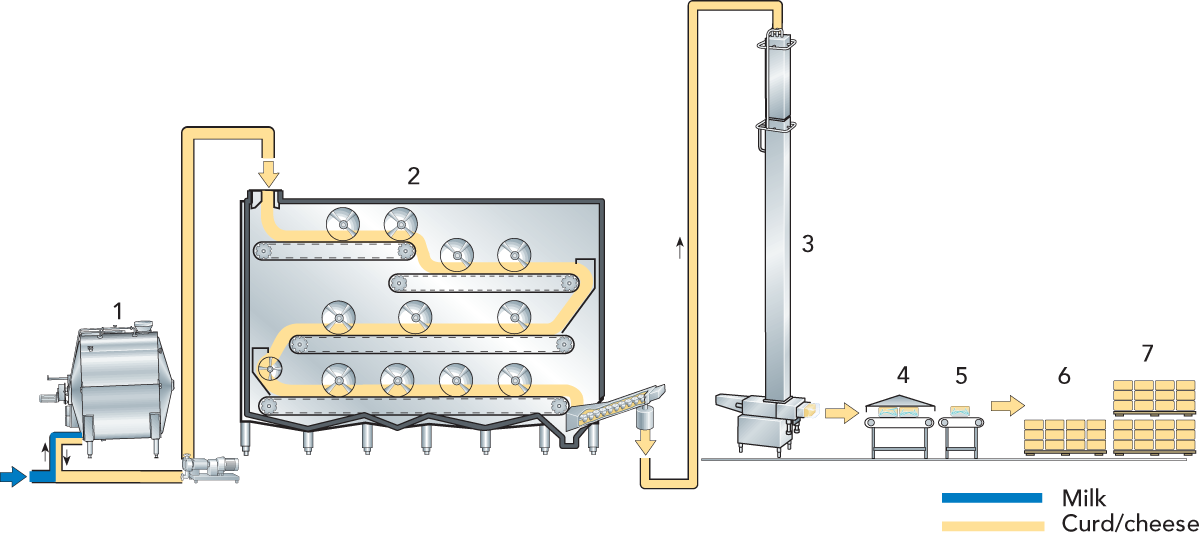

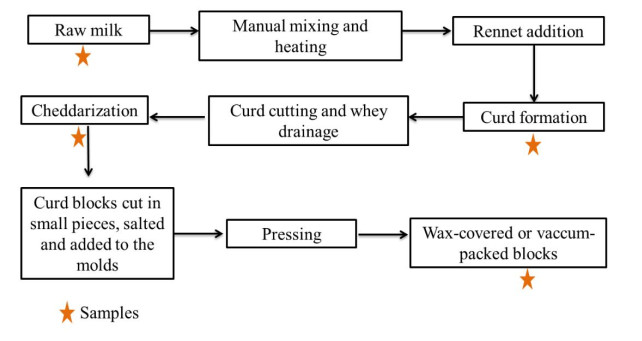

In this video lecture, the process of manufacturing of cheddar cheese is explained in detail. All the unit operations involved in the manufacturing process ... Figure 2 shows a schematic diagram of the cheese manufacturing process. Figure 2. The cheese manufacturing process. Thus, microbes can not only be harmful to society but also can be manipulated in a variety of ways for the benefit of society. Particularly in the preservation and production of food, microbes have proven to be useful and essential. Flow Chart of cheese Production. Find this Pin and more on Flow Chart of Cheese Production by zalda hughes. Process Flow. Engineering. Diagram. Chart. Cheese. Milk. Google Search.

Cheese making process diagram. Process cheese is made using natural cheese plus other ingredients that are cooked together to change the textural and/or melting properties and increase shelf life. Ingredients . The main ingredient in cheese is milk. Cheese is made using cow, goat, sheep, water buffalo or a blend of these milks. by BJ Jones · 1999 · Cited by 1 — Flow diagram of cheese making process. 3. 1.2 OST tank horizontal cheese vat. 5. 1.3. Section of the knives/stirrers used in the OST tanks.104 pages The following process is used to make Cheddar cheese: Process Notes Raw Milk Pasteurise Heat to 63 °C for 30 minutes (see Technical Brief: Pasteurised milk ). Cool Cool with stirring to 25-30°C. Inoculate Starter culture Place in a stainless steel cheese vat and add 2% starter culture for faster acid production (less for a slower ... Diagram 1- Standard process for cheese making MILK The raw material, milk, can be from different species: cow (for cow cheese), buffalo (for buffalo cheese), sheep (for sheep cheese), goat (for goat cheese), or it can be a mixture of milks from more than one species (in this case we speak of mixed milk cheese).

1 Fig. 1.1 is a flow diagram showing the main stages involved in making cheese. The starting material is milk, which contains the protein, casein. milk is heated to 72 °C for 15 seconds (pasteurisation) milk is cooled and kept at 30 °C for the next two stages Whey comprises 80 - 90 % of the total volume of milk entering the process and contains about 50 % of the nutrients in the original milk: soluble protein, lactose, vitamins and minerals. Whey as a by-product from the manufacture of hard, semi-hard or soft cheese and rennet casein is known as sweet whey and has a pH of 5.9 - 6.6. product. However, seldom do small-scale cheese plants implement their own HACCP plans. HACCP is a plant-specific and product-specific quality system (Morris, 1997). To boost the quality of their cheese products, it would be of great benefit to small-scale cheese plants if they develop and implement HACCP plan based on their specific productions. Download scientific diagram | DGGE profiles of 16S rRNA gene V6-V8 regions obtained from samples of cheese manufactured with L. salivarius CECT5713 using universal primers U968-GC-f and L1401-r ...

Process cheese is made using natural cheese plus other ingredients that are cooked together to change the textural and/or melting properties and increase shelf life. Ingredients. The main ingredient in cheese is milk. Cheese is made using cow, goat, sheep, water buffalo or a blend of these milks. Owing to the technical developments, promotion of dairy hygiene and unremunerated propagation of modern cheese-making techniques he suggested, he has been described as the father of Cheddar cheese. Harding introduced new equipment into the process of cheese making, including his 'revolving breaker' for curd cutting, saving much manual effort. The diagram illustrates the way milk is produced and processed into cheese, cream and butter and packaged for sale to consumers. Overall, there are eight stages in the process, starting with cows grazing on the grass, to the milk processed at the dairy and the sale of dairy products in supermarkets and shops. In the separator method for cream cheese making with the production diagram as shown in Figure 1, the starting mixture for making cream cheese is standardized to 8-14% fat for double cream cheese, and to 3-5% fat for single cream cheese. Then the mix is homogenized (12-14 MPa at 50-55ºC), pasteurized (66-68ºC for 30 min or

Studying the cheese making process we could conclude that the bioreactor has to have a pH 5.2, working in a temperature of 33oC in 30 to 40 minutes. With this, the bioreactor has to content pressure valve, control parameters, cooling jacket, cooling system, whey removal and exhaust. It has to have an entrance to the starting material, a ...

III-Dairy-D-Cheese-5 Figure 2 Diagram showing the action of rennet on the casein micelle. The enzyme in rennet cleaves the κ-casein releasing a large peptide. The surface of the ... The pH of the curd falls during this process and whey continues to exude. Again, in large scale manufacture, this is done in large machines (Figure 4).

Step 2: Acidify the Milk. There are many ways to make cheese but the first 'split in the road' is how you acidify the milk. One way is to dump acid (vinegar or citric acid) right into the milk to get the correct acidity. This process (called direct acidification) leads to cheeses such as ricotta and mascarpone.

Making cheese is both an art and a science. Cheesemakers rely as much on measurements of pH levels and inoculations of specific molds as they do their own senses of sight, touch, and smell. There are six important steps in cheesemaking: acidification, coagulation, separating curds and whey, salting, shaping, and ripening.

The object of cheese making is to turn milk into a solid by removing some of this water and acidifying the milk - the amount to be removed depending on how long you want the cheese to last. Drier (and thus, harder) cheeses keep fresh longer. Setting milk into curd The first step to removing the excess water is by separating the milk into curd ...

Just like in canning, preserving, and bread making, cleanliness is important in cheesemaking as well. The process of cheesemaking will provide an ideal environment for friendly bacteria to ripen your milk; being sure your environment is clean will help the cultures stay strong, happy and healthy without having to compete against unwanted bacteria.

There are 7 stages in the process of making cheese. Find out the first 5 steps below, and the last 2 steps on our Facebook page: Cheese of Europe Hong Kong. 1. From the Milking Barn to the Dairy Plant. Just like any dairy product, the first stage of cheese production starts at the dairy farm. Here, farmers milk the cows, a process that's been ...

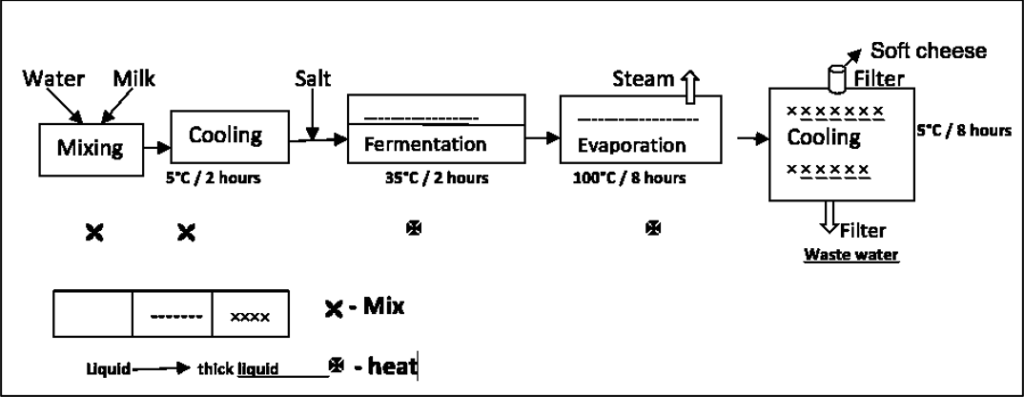

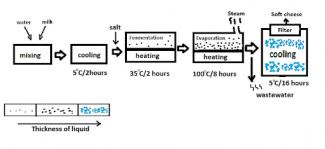

The given process illustrates the information about steps involved in production of soft cheese. Overall, it is clear that the process includes mainly 5 stages. The process begins by mixing ingredients and contaminates at obtaining soft cheese. To begin with, a mixture is prepared by mixing water and milk in a container and followed by cooling process.

Cheese is a milk concentrate, the basic solids of which consist mainly of protein (actually casein) and fat. The residual liquid is called whey. As a rule of thumb, the casein and fat in the milk are concentrated approximately 10 times in production of hard and some semi-hard types of cheese. No strict definition of the concept of cheese is ...

The Cheese-Making Process. Now, let's take a closer look at the magic of cheese making, starting with simple milk all the way to the finished product. Step 1: Preparing the Milk. Since milk is the star of the show, to make cheese just right, you need your milk to be just right.

The flow chart illustrates how soft cheese is made through many stages. It is clear that this process is relatively complex with six main stages. In particular, it begins with adding to water and milk, and ends at making soft cheese. At the beginning of the production of this process, water is mixed with milk and put into a container. Next, this mixture is cooled at 5 Celsius in 2 hours.

The diagram below shows the process of making soft cheese. Summarise the information by selecting and reporting the main features and make comparisons where relevant. The given picture illustrates the steps in the production of soft cheese. Overall, it can be seen that the process of making soft cheese involves five main steps. The process … IELTS Academic Task1 5th September 2020 Read More »

Flow Chart of cheese Production. Find this Pin and more on Flow Chart of Cheese Production by zalda hughes. Process Flow. Engineering. Diagram. Chart. Cheese. Milk. Google Search.

Figure 2 shows a schematic diagram of the cheese manufacturing process. Figure 2. The cheese manufacturing process. Thus, microbes can not only be harmful to society but also can be manipulated in a variety of ways for the benefit of society. Particularly in the preservation and production of food, microbes have proven to be useful and essential.

In this video lecture, the process of manufacturing of cheddar cheese is explained in detail. All the unit operations involved in the manufacturing process ...

0 Response to "40 cheese making process diagram"

Post a Comment