38 constant speed propeller diagram

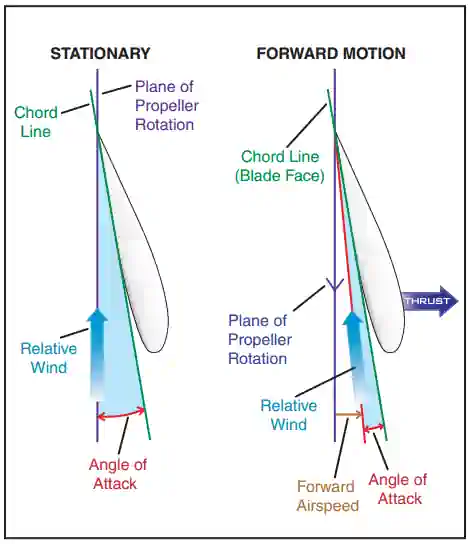

The image given is for constant pitch propeller, is there a similar diagram for constant speed propeller? aerodynamics propeller angle-of-attack blade constant-speed-propeller. Share. Improve this question. Follow edited May 3 at 1:25. 0scar. 1,154 4 4 silver badges 19 19 bronze badges.

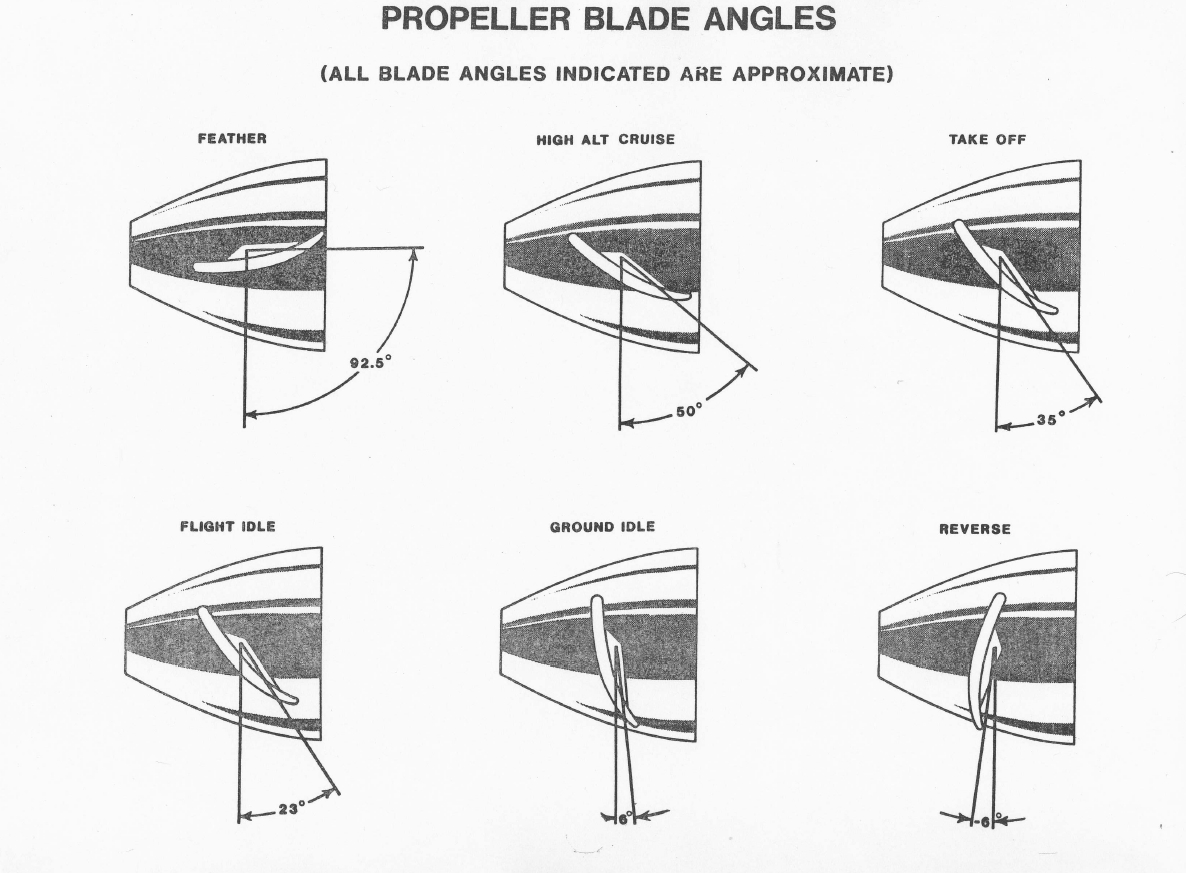

the propeller; except during momentary periods in order to maintain constant RPM. Not can the propeller be reversed at airspeeds above a certain airspeed because the propeller will windmill at governing speed. Thus the propeller cannot be put into reverse pitch The propeller can be reversed during power-off descent after the

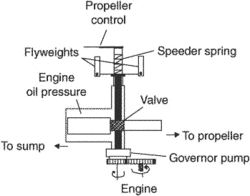

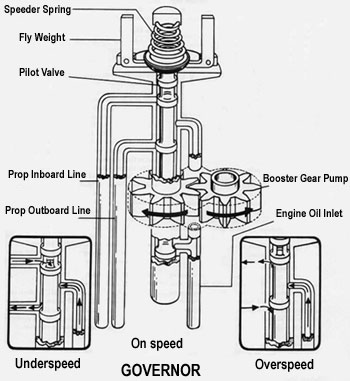

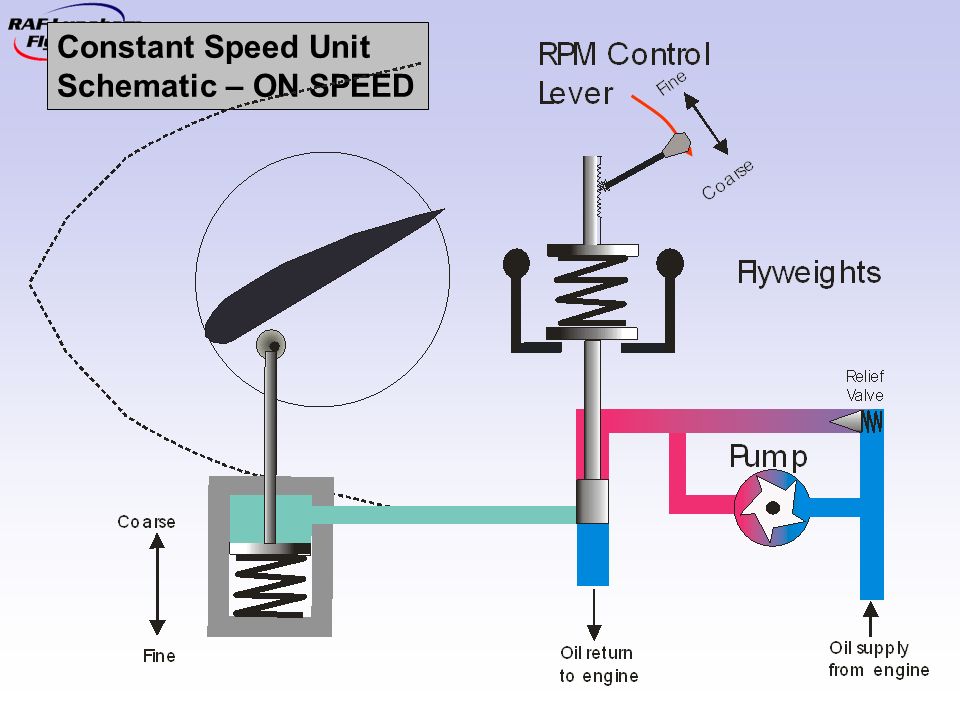

A constant-speed propeller is a variable-pitch propeller that automatically changes its blade pitch in order to maintain a chosen rotational speed, regardless of the operational conditions of the aircraft. This is achieved by use of a constant-speed unit (CSU) or propeller governor, which automatically changes the propeller's blade pitch.. Most engines produce their maximum power in a narrow ...

Constant speed propeller diagram

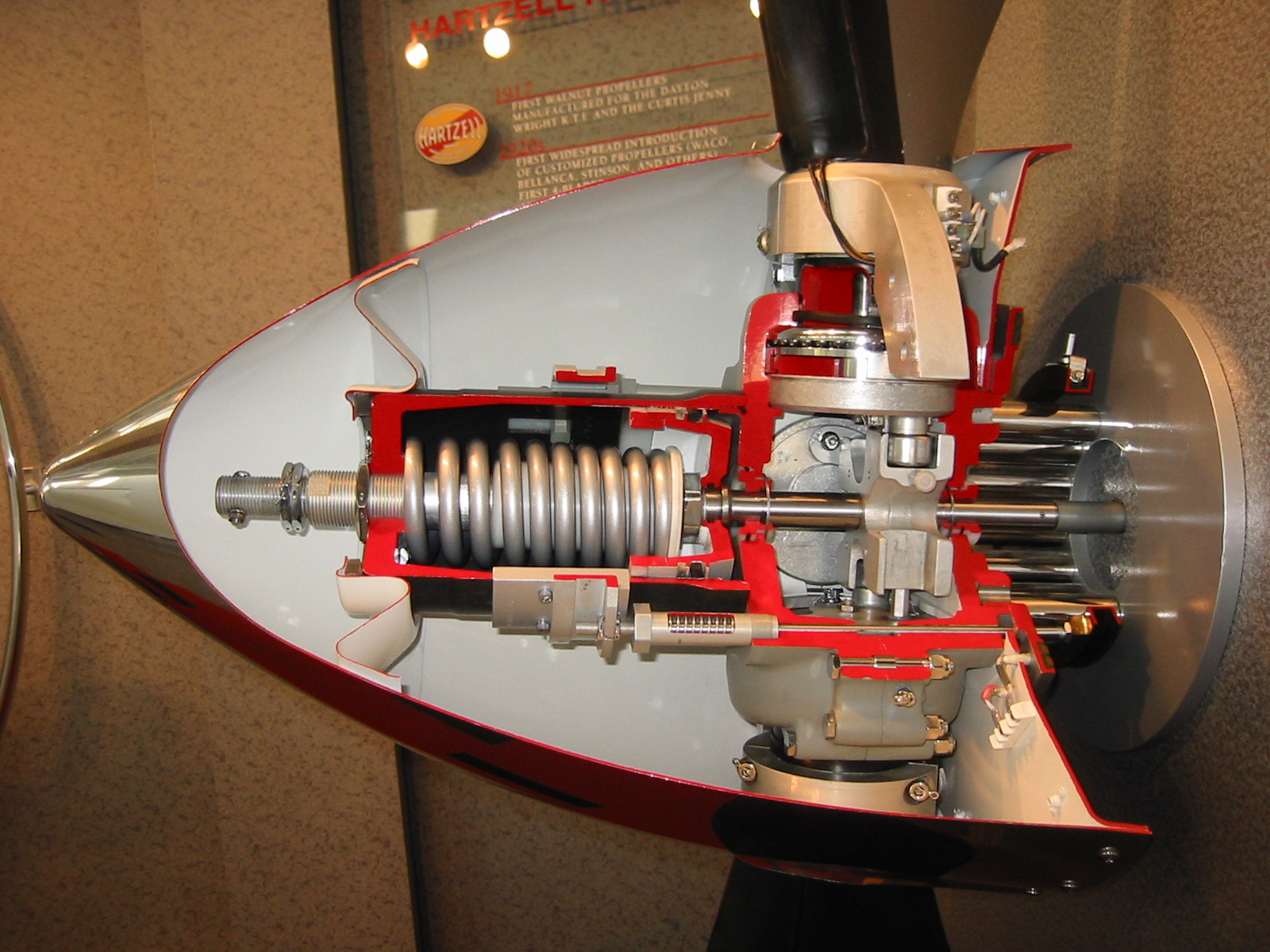

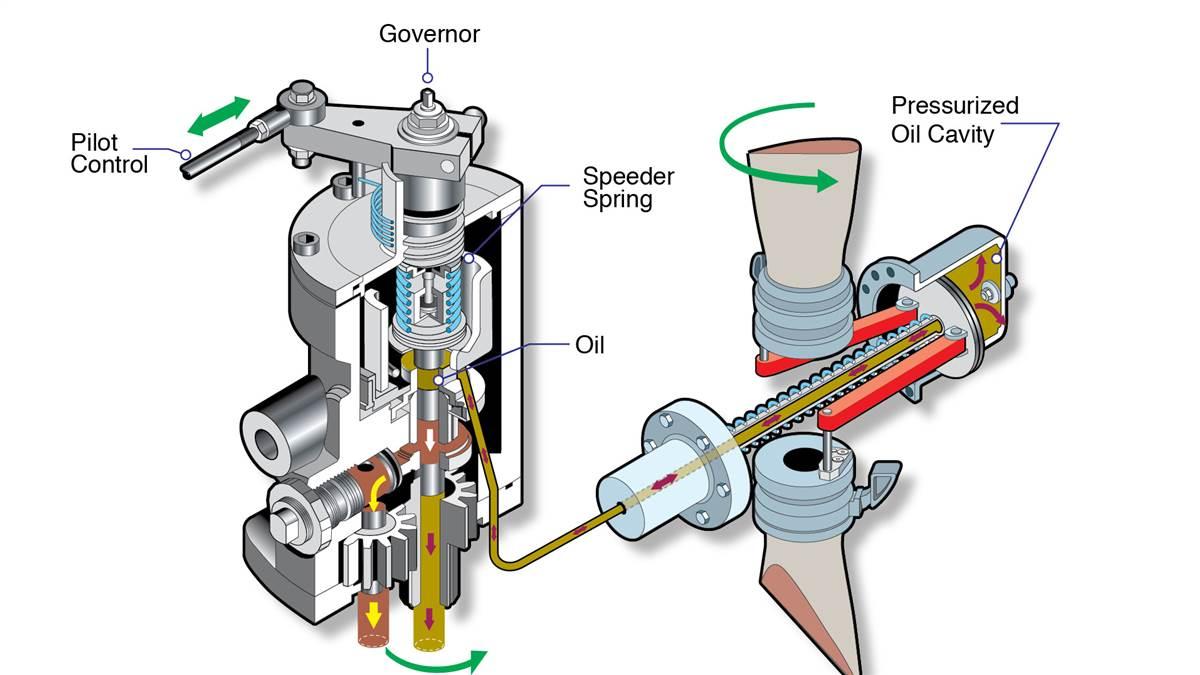

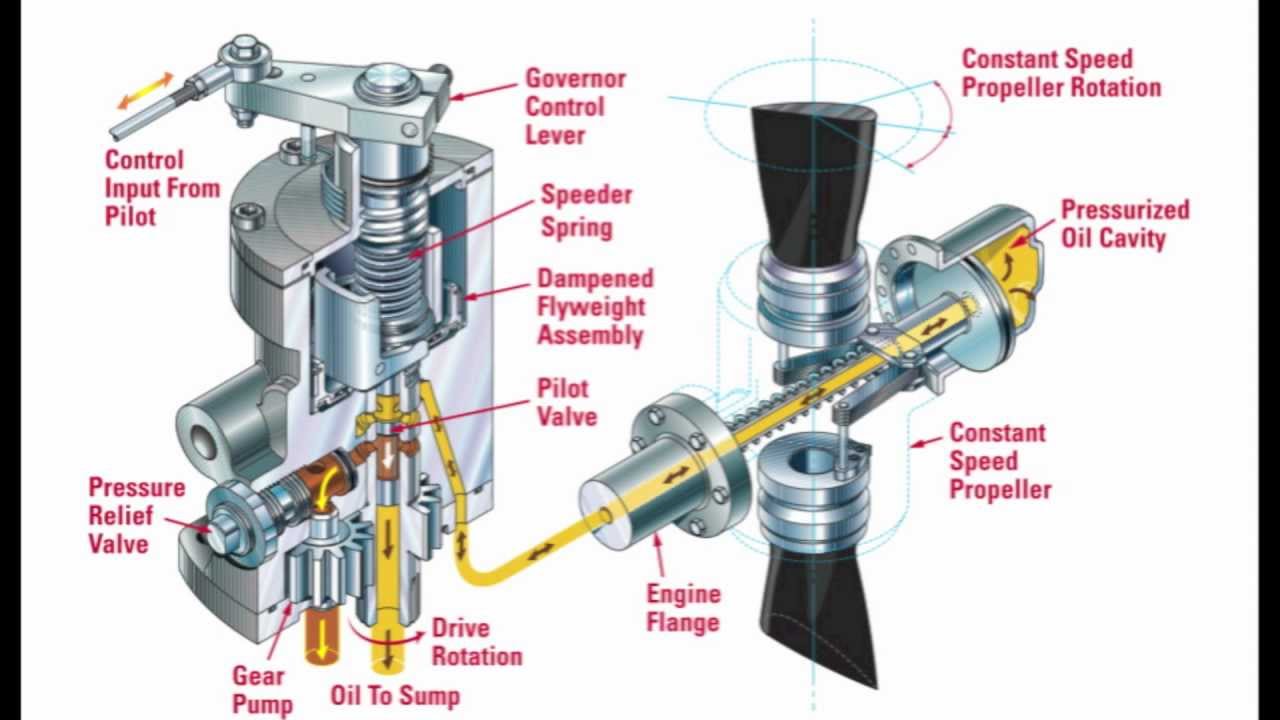

Description. A constant speed propeller is a propeller that is designed to automatically change its blade pitch to allow it to maintain a constant RPM, irrespective of the amount of engine torque being produced or the airspeed or altitude at which the aircraft is flying. This is accomplished by means of a Constant Speed Unit, or governor, integrated into the propeller design.

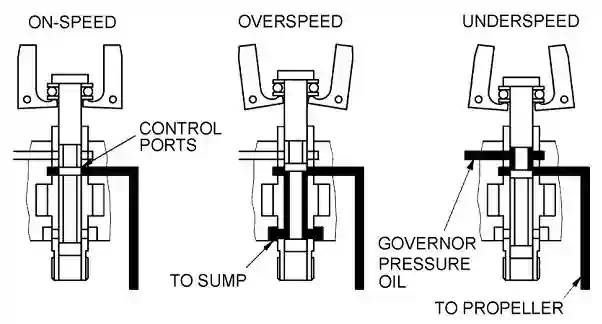

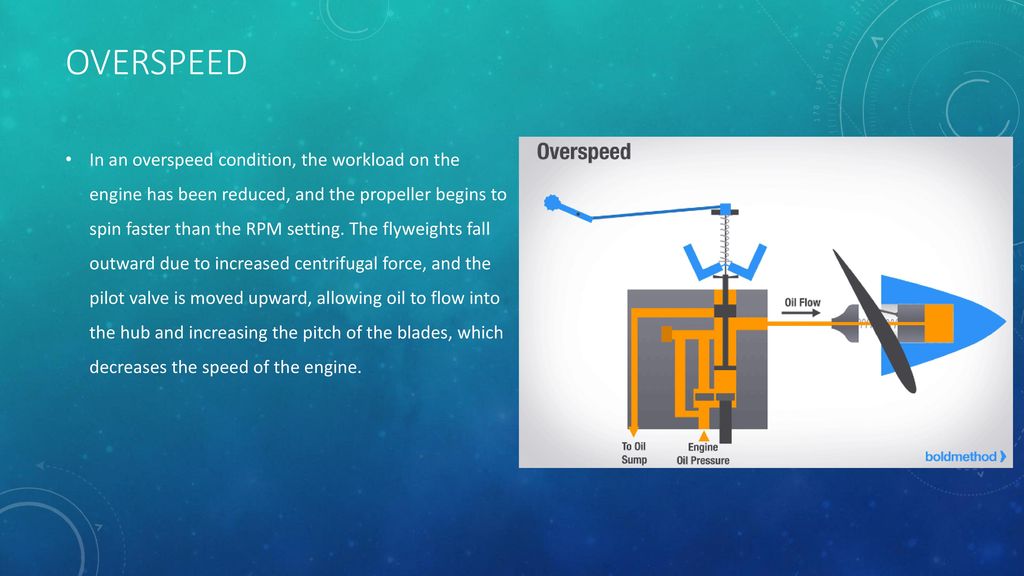

propellers) (Diagram courtesy of McCauley-Textron) At constant-speed, an over speed condition results and airspeed increases when the aero plane begins a descent or engine power is increased. Since the pitch of the propeller blades is too low to absorb engine power, the engine RPM begins to increase.

Converts In-Flight Adjustable IVOPROP into the constant Speed Propeller Plugs into existing wire harness Size 2″ x 4″ x 1″ Price $350 OPERATION - Red 1 led lights up when governor wants to drive prop to lower pitch - Red 2 lights up anytime the prop is actually driven to lower pitch. Goes out if prop reached its low mechanical pitch ...

Constant speed propeller diagram.

• The efficiency of the propeller P is defined as: P =P (5.7), where: THP is the thrust horsepower of the engine, V= (5.8) • Typically, P 9 for a good constant-speed propeller at the engine rated rpm and aircraft operating airspeed of below 300 ft/s. • The available thrust of the engine/propeller combination is then given by: SL SL P

Definition Reverse pitch, in a variable pitch propeller or constant speed propeller, refers to a blade pitch angle that has a negative value. Description When installed, reverse pitch is a pilot selectable feature of a constant speed or variable pitch propeller which allows the blade pitch to be decreased to a negative value. Negative pitch angles result in the thrust generated by the ...

A feathering McCauley propeller compared to a McCauley constant-speed propeller. Figure 4-5. A version of the centrifugal latch mechanism used to prevent a feathering propeller from feathering when the engine is shut down on the gorund. engine to windmill. Once the engine is windmilling, the ignition and fuel for the engine is turned on

You want the propeller efficiency to follow a nearly straight line connecting each curve in the diagram at its tip. Thus: the constant-speed propeller. The blades will constantly adjust their angle to result in a given engine/propeller speed. If the throttle's high and the engine isn't spinning fast enough, the blades will angle closer to ...

Figure 2. Constant-speed feathering propeller. While the propeller is operating, the following forces are constantly present: 1) spring force, 2) counterweight force, 3) centrifugal twisting moment of each blade, and 4) blade aerodynamic twisting forces. The spring and counterweight forces attempt to rotate the blades to higher blade angle ...

holding the pitch of the blades constant until the oil flow to or from the propeller is establishedbythegovernor. 5 5 ... positive response by the propeller. The rotational speed of the flyweight assembly varies directly with engine speed and controls. 7 thepositionofthepilotvalve.Dependingonits

There are two main types of propeller assemblies, fixed-pitch and constant-speed. With a fixed-pitch propeller, the blade is attached to the hub at a permanent angle. With a constant-speed—or variable-pitch— propeller, the root of the blade can rotate to any position between two limits in a range, thereby changing the angle of the blade

1. RUNUP. Taking a constant-speed airplane through its pre-takeoff routine is a bit more involved. The propeller control must be pulled back all the way at least once, and more may be required to check manifold pressure, rpm, and oil pressure—all of which will change as the propeller pitch changes.

For either the fixed pitch or constant speed prop, the blade twist can only be suitable for one speed - the design air speed. At any other speed, off-point losses will occur but will be less for the constant speed propeller. Diagram 9, Prop Load Curve, clarifies the point made above and in the previous section on fixed pitch propellers.

The twist in propeller blades is called pitch. If pitch is too great, it creates drag and robs you of takeoff power. Too little, and you are forced to run the engine faster to achieve cruise speed. Most likely your trainer is not equipped with a constant-speed propeller, but one with fixed pitch. Your fixed-pitch propeller isn't the best for takeoff but not bad, and isn't the best for ...

In case you are wondering, multiplying "engine hp" by 550 produces the number of ft - lb per second in that number of hp, so as to match the units in the numerator of the equation (8th grade algebra).. The general relationship between engine power, thrust, and propeller power across a given speed envelope in a constant atmospheric model is shown in Figure 2 below.

11. 7. 1 Overview of propeller performance. Each propeller blade is a rotating airfoil which produces lift and drag, and because of a (complex helical) trailing vortex system has an induced upwash and an induced downwash. Figure 11.24 shows a schematic of a propeller.

pitch for constant-speed systems or low pitch for full-feathering systems. (Figs. 1A & 1B) When the selected RPM is reached and oppos-ing forces are equal, oil flow to the propeller is reduced and the piston also stops. The piston will remain in this position, maintaining the Propeller Operation pitch of the blades until oil flow to or from the

n = Propeller speed, and α= the constant ship speed coefficient. For any combination of power and speed, each point on the constant ship speed line gives the same ship speed. When such a constant ship speed line is drawn into the layout diagram through a specified

Constant speed propellers work by varying the pitch of the propeller blades. As the blade angle is increased, it produces more lift (thrust). At the same time, more torque is required to spin the prop, and the engine slows down. The opposite is true when the blade angle is decreased: the torque required is decreased, and the engine speeds up.

To use this diagram, you need to know the propeller area A $_O$, the inflow velocity v $_A$ (which is normally lower than the ship's speed due to the vicinity of the hull), the thrust T, the rotation rate n in rev/sec and the propeller diameter D. With a known advance coefficient you start at the bottom and move up on the diagonal lines until ...

The governor then sets the blade angle to try and achieve that rpm. At idle with the prop control full forward, the engine is at a lower rpm than redline so the governor flattens the blades to try and increase speed. The governor is blind to power, MAP, etc, all it can do is change blade angle in response to rpm.

VARIABLE PITCH CONSTANT SPEED PROPELLER ASSEMBLY Filed Aug. 22, 1940 4 Sheets-Sheet l Y iNVENTOR. m s. W Y Wuealm. 5 -NOV. 28, 1944 w, s HQQVER 12,363,670, ... as shown in the unfeathering diagram, Fig. 9. Oil flows from pump 55 to valve 26, as shown by the arrows, and thence to the torque motor 49. ...

The Design and Operation of Hollow-Shafted Constant Speed Propellers Part 2: The Curtiss Electric Propeller by Tom Fey. Torque Meter, Vol, 2, Number 2, Spring 2003. US Patent 1,986,229 for a Controllable Pitch Propeller granted to Robert M. Stanley, 1 January 1935.

An efficient propeller is one which has the least amount of slippage and therefore converts more engine horsepower into thrust. A constant speed propeller keeps the propeller pitch adjusted for maximum efficiency for most conditions of flight. Takeoff. During takeoff we need the most power and thrust.

A constant speed propeller is a variable pitch propeller that adjusts the pitch of the propeller blades automatically to maintain a certain RPM. Unlike fixed-pitch propellers, which only operate at optimal efficiency during one stage of flight, constant speed propellers provide peak performance during every phase of flight.

What is an advantage to Constant Speed Propeller? ... Show the cycle on a T-s diagram relative to the saturation lines, and determine (a) the thermal efficiency, (b) the quality at the end of the isothermal heat-rejection process, and (c) the net work output. Verified answer. ENGINEERING.

A hydromatic propeller has a double-acting governor that uses oil pressure on both sides of the propeller piston. Many larger turboprop systems also use this type of system. The governors are similar in construction and principle of operation in normal constant-speed systems. The major difference is in the pitch-changing mechanism.

0 Response to "38 constant speed propeller diagram"

Post a Comment