39 iron carbide phase diagram

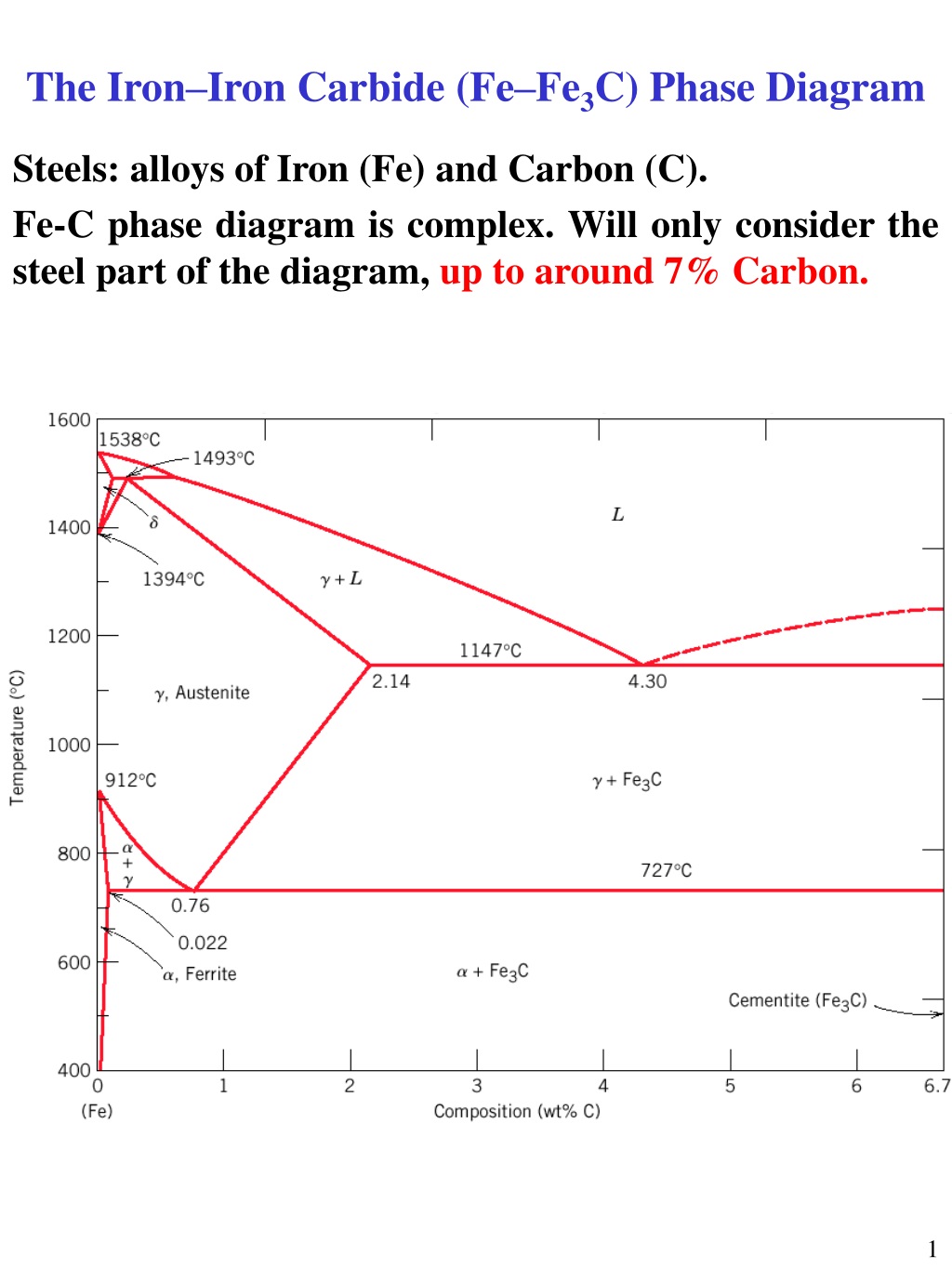

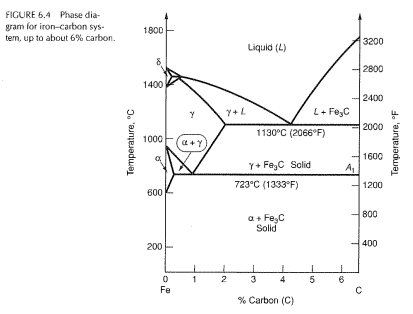

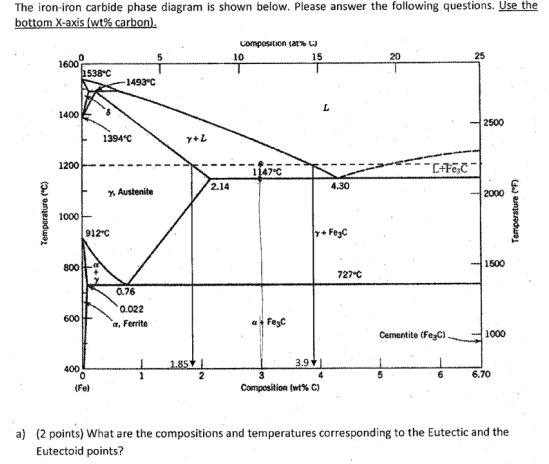

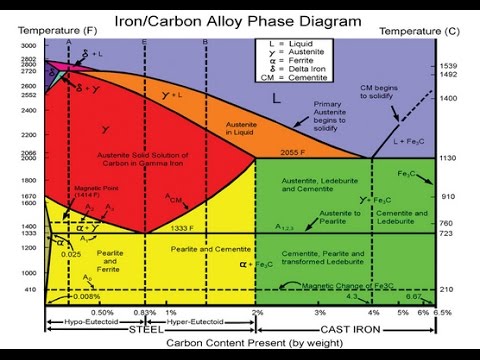

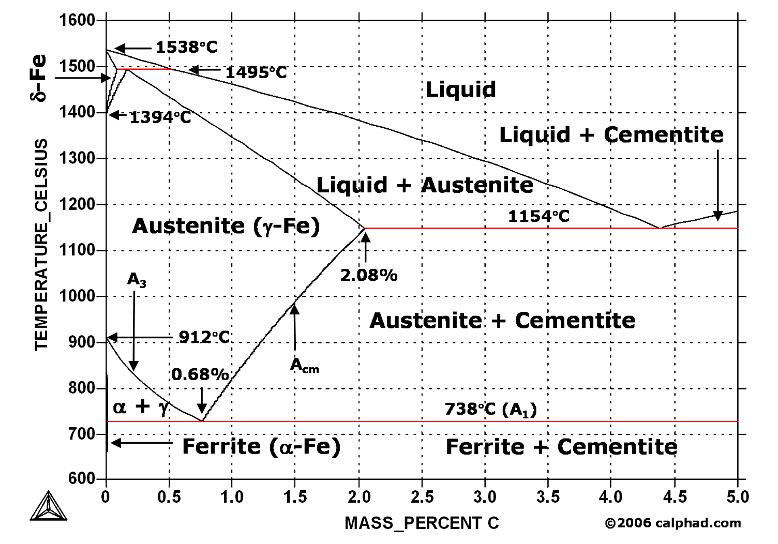

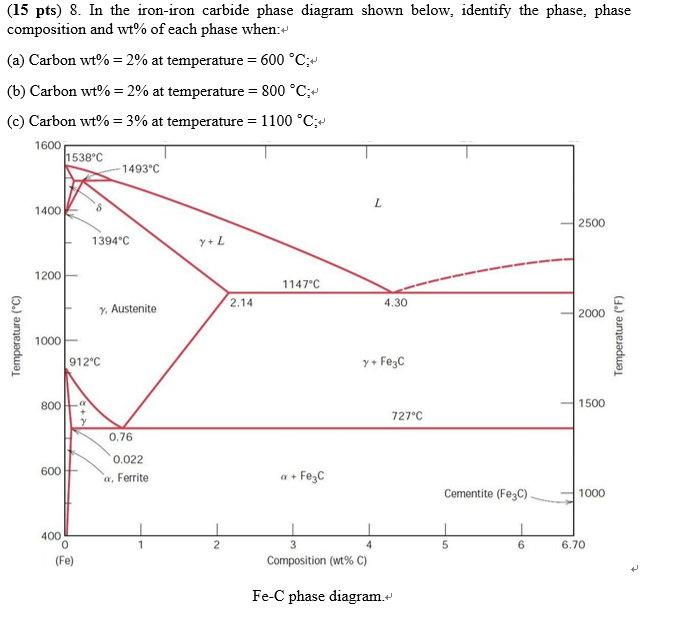

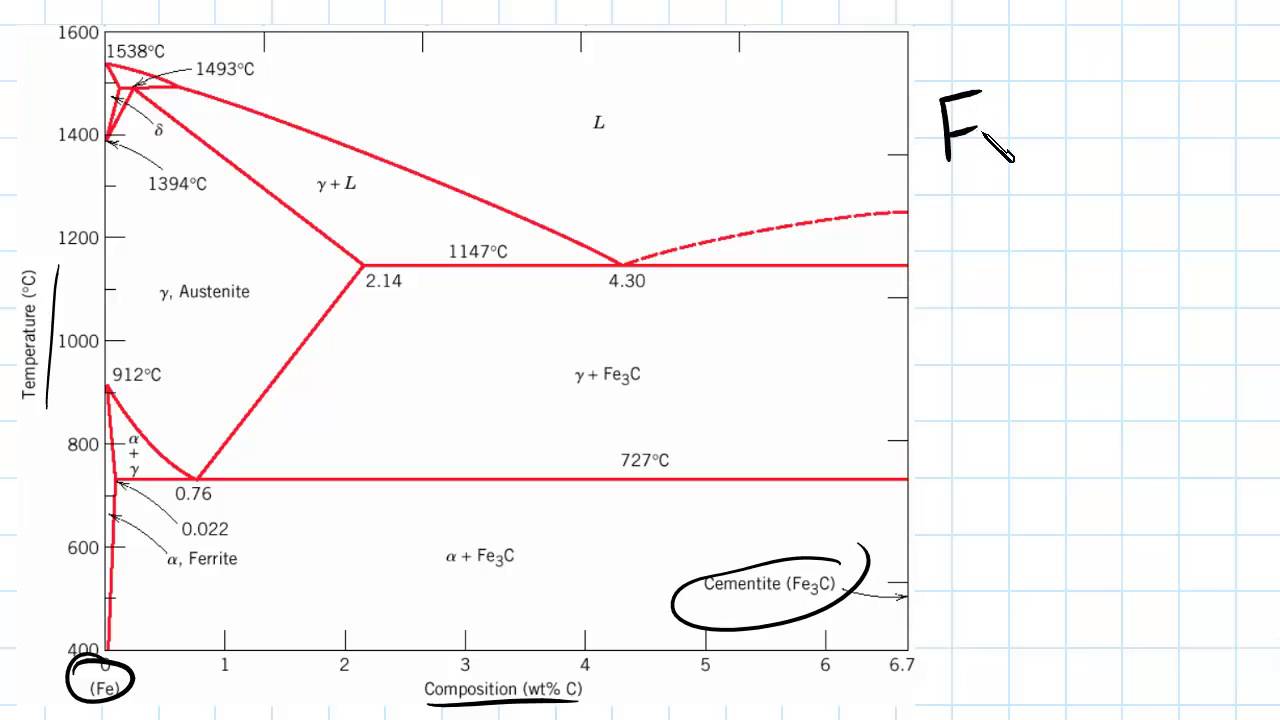

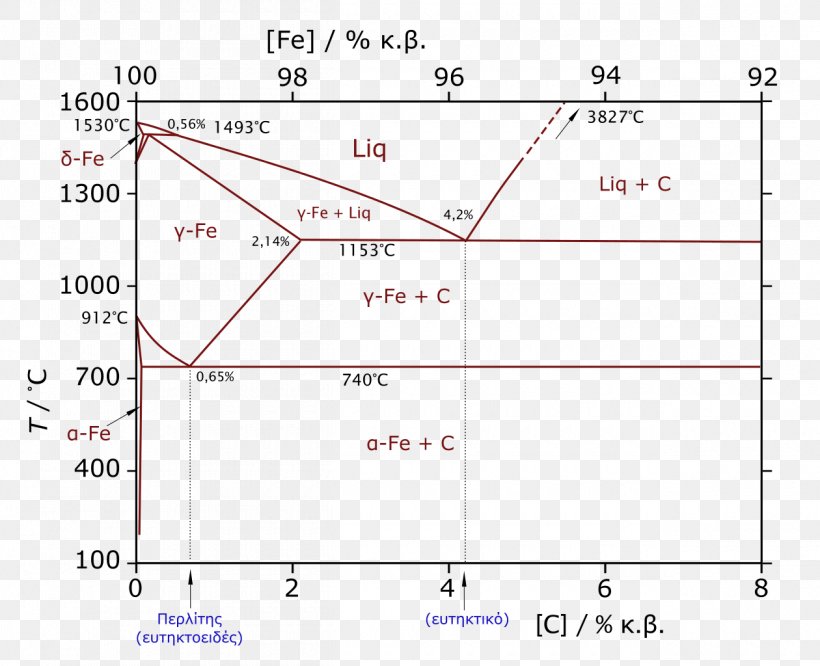

The Fe-C phase diagram is a fairly complex one, but we will only consider the Cementite Cementite or iron carbide (Fe 3C) is an intermetallic. Answer to From the Fe-Fe 3C phase diagram below, answer the following questions. (a) (8 pts) There are three transformation reactio. Fe-Fe 3C phase diagram. Iron and Steel.

**Electron Structure:** The Group 5 elements are nearing the middle of the transition elements. Group 5 elements have five bonding electrons each due to hybridization (see below), and they are higher melting than the Group 4 elements (Ti, Zr and Hf). This logically follows the idea that the more bonding electrons an element has, the stronger its bonding will be, and therefore the higher the melting temperature. V, Nb and Ta have electron structures of: *(inert gas core) + d^3 + s^2* which hybr...

The iron-iron carbide phase diagram is shown in the Animated Figure 9.24. What is the carbon concentration of an iron-carbon alloy just below the eutectoid for which the fraction of total ferrite is 0.70? The iron-iron carbide phase diagram is shown in the Animated Figure 9.24.

Iron carbide phase diagram

Iron-carbon phase diagram. 12/07/2021. The iron-carbon phase diagram describes the iron-carbon system of alloys containing up to 6.67% of carbon, describe the phases compositions and their transformations occurring with the alloys during their cooling or heating. Carbon content 6.67% corresponds to the fixed composition of the iron carbide Fe 3 C.

Phase diagrams are maps that help us track microstructural development during the slow cooling of an alloy. The Fe-Fe3C (iron carbide) phase diagram is an example of a _____ diagram, with special relevance to steelmaking. 1 point. eutectoid; eutectic; temperature versus time; 18. Question 18 Quenching a eutectoid steel below about 200

Although it is heterogeneous, these phases behave like homogeneous pure bodies. Steel is between 0 and 2.06 mass percent of carbon. Cast iron is between 2.06 ...

Iron carbide phase diagram.

Hi everyone, I'm in a Materials and Mechanics class for an engineering curriculum, and my professor was not able to find anything about the differences in the mechanical properties of Hypoeutectoid steels and Hypereutectoid steels for the Iron-Iron Carbide Phase Diagram and why you would choose one over the other specifically for mechanical properties. Just to reiterate, I understand why chemically you would choose one over the other, but not why mechanically, if there even is a reason why. I...

Middle English iron, iren, yron, from Old English iren, variant (with rhotacism of -s-) of isen, later form of isern, isærn "the metal iron; an iron weapon or instrument," from Proto-Germanic *isarn (source also of Old Saxon isarn, Old Frisian isern, Old Norse isarn, Middle Dutch iser, Old High German isarn, German Eisen). This perhaps is an early borrowing of Celtic *isarnon (compare Old Irish iarn, Welsh haiarn), which Watkins suggests is from PIE *is-(e)ro- "powerful, holy," from PIE *eis "strong" (source also of Sanskrit isirah "vigorous, strong," Greek ieros "strong"), on the notion of "holy metal" or "strong metal" (in contrast to softer bronze). It was both an adjective and a noun in Old English, but in form it is an adjective. The alternative isen survived into early Middle English as izen. In southern England the Middle English word tended to be ire, yre, with loss of -n, perhaps regarded as an inflection; in the north and Scotland, however, the word tended to be contracted to irn, yrn, still detecta

A phase diagram in physical chemistry, engineering, mineralogy, and materials science is a type of chart used to show conditions (pressure, temperature, volume, etc.) at which thermodynamically distinct phases (such as solid, liquid or gaseous states) occur and coexist at equilibrium

Indicate temperatures and phases in the Cu-Ni phase diagram. Draw an equilibrium diagram for Iron-Iron-Carbide. What is a ceramic material? Discuss the allotropy phenomena. Explain the requirement of heat treatment methods for metals. Mention various types of ceramic materials. Describe what powder metallurgy is?

Iron carbon phase diagram pdf. 2021 2020. Issue. 1 January - Volume 70, Issue 1 1 February - Volume 70, Issue 2 1 March - Volume 70, Issue 3 1 April - Volume 70, Issue 4 1 May - Volume 70, Issue 5 1 June - Volume 70, Issue 6 1 July - Volume 70, Issue 7 1 August - Volume 70, Issue 8 1 September - Volume 70, Issue 9 1 October - Volume 70, Issue 10.

Different steels have different TTT and CCT diagram s. So the. The iron - iron carbide phase diagram.L + Fe3C. M The complete TTT diagram for an iron-carbon alloy of eutectoid composition. Imagine, for example, some pure iron that was kept at a temperature of oC ( .. Here is the "official" isothermal TTT diagram for eutectoid carbon steel. Fig. 4 shows the schematic TTT diagram for eutectoid ...

Phase Diagram (equilibrium or constitutional diagram): ... (Fe) solid solution in delta iron (iv). Fe 3 C (iron carbide) or cementite - an inter-metallic compound and liquid Fe-C solution. Four invariant reactions are eutectic, Eutectoid, monotectic and peritectic.

c. 1400, irenen, "to make of iron," from iron (n.). Meaning "shackle with irons" is from 1650s. Meaning "press clothes" (with a heated flat-iron) is recorded from 1670s. Related: Ironed; ironing.

Jun 1, 2012 — Iron-carbon phase diagram describes the iron-carbon system of alloys containing up to 6.67% of carbon, discloses the phases compositions and ...

"to synchronize, adjust the phase of so as to synchronize," 1895, from phase (n.) in the physics sense of "particular stage or point in a recurring sequence of movement or changes" (1861). Earlier as a bad spelling of faze. Meaning "to carry out gradually" is from 1949, hence phase in "introduce gradually" (1954), phase out "take out gradually in planned stages" (1954). Related: Phased; phasing.

This process consists of homogenisation or grain refinement to obtain uniformity in the material microstructure. The material is heated to a temperature above the upper critical line of the iron carbide phase diagram to produce a homogeneous austenitic phase. This is then followed by a cooling phase in slightly agitated air to form ferrite.

TTT diagram of steel indicates the time-temperature and transformation curve. This means transformation is dependent upon time, temperature, and cooling mechanism. Difference between phase diagram and TTT diagram of steel. For a clear understanding of this diagram, it is better to understand the phase transformation of the Fe-Fe3C curve.

from German eiserne kreuz, instituted 1813 by Frederick Wilhelm III of Prussia, originally for distinguished military service in the wars against Napoleon.

1918 (Venn's diagram is from 1904), named for English logician John Venn (1834-1923) of Cambridge, who explained them in the book "Symbolic Logic" (1881).

Okay, so after my last post, there was a request for details about phase states other than what we can see documented in the TTT diagram. As I've been writing this, it's kind of evolved into a primer on the different phase states and what they mean. If my last post was too long for you, I'm sorry to say this one is probably longer. So, let's get ourselves started. The first thing we need to discuss is what is steel? What makes steel different from iron, and where does cast iron come into this m...

Figure 1 shows the equilibrium diagram for combinations of carbon in a solid solution of iron. The diagram shows iron and carbons combined to form Fe-Fe3C ...

1610s, "an illustrative figure giving only the outlines or general scheme of the object;" 1640s in geometry, "a drawing for the purpose of demonstrating the properties of a figure;" from French diagramme, from Latin diagramma "a scale, a musical scale," from Greek diagramma "geometric figure, that which is marked out by lines," from diagraphein "mark out by lines, delineate," from dia "across, through" (see dia-) + graphein "write, mark, draw" (see -graphy). Related: Diagrammatic; diagrammatically. The verb, "to draw or put in the form of a diagram," is by 1822, from the noun. Related: Diagrammed; diagramming.

Hello! I am working on homework for my material science course (mechanics of materials elsewhere) and have been having a hard time understanding this diagram. Let me clarify, I understand the all of the phase boundary lines and each phase and what is taking place in each. Yet I am confused when it comes to the eutectoid region. If anyone has any advice or some guide to understanding this better, that'd be great. I don't really understand computing the weight fraction of ferrite and cementite...

However, since martensite is a non-equilibrium phase on the iron-iron carbide phase diagram, it has not been shown that warming the part after the cryogenic treatment results in the re-transformation of the induced martensite back to austenite or to ferrite plus cementite, negating the hardening effect.

So I need someone to check some of these, so I might crosspost this to other subreddits, if you know any, please do. Or if you are an expert yourself, please correct me if there's any mistakes. But I did watch Dr. Stone in an *Anime Streaming website*, I posted some interesting comments in the discussions of Dr. Stone Episodes. I will post them in a chronological order with the matching episodes. Although, I think it's a bad idea to post this in a whole one post. Because no one gonna read it t...

My husband and I are just getting started in forging as a hobby. It's something we have wanted to do for a long time and we finally have the time to do so. I have a degree in Materials Science and engineering. I have wanted to do my own smithing and forging since the first time I saw an Iron-Iron carbide phase diagram, and saw just how many different grain structures steel could have with do many varying properties. So I am starting out in this hobby with the theory knowledge regarding grai...

Hello engineers I have ASTM A500 grade B steel tubing that is being heated with a torch enough to bend it and I'm wondering how it will affect it's microstructure, yield point and ultimate tensile strength. I assume this will correlate with how hot the tubing gets. Therefore, my attention is at phase diagrams. From Matweb I am getting these values for the chemical composition of ASTM A500 Gr. B. Carbon 0.30% Cu 0.18% Iron 99% Phosphorous .050% Sulfur 0.063% I was originally going to ...

Iron carbon phase diagram google search knives metal sumber : pinterest fe c sumber : infosteel pertamaxxx blog diagram fe fe3c sumber : blog.ub.ac.id muddiest point phase diagrams i eutectic calculations sumber : juli 2019 aceng sambas sumber : komputasirobotic juli 2019 aceng sambas sumber.

Iron–Iron Carbide (Fe–Fe3C) Phase Diagram. In their simplest form, steels are alloys of Iron (Fe) and Carbon (C). The Fe-C phase diagram is a.7 pages

1) Equilibrium phase diagrams, Particle strengthening by precipitation and precipitation reactions 2) Kinetics of nucleation and growth 3) The iron-carbon system, phase transformations

having following topics Crystallography:- Crystal, space lattice, unit cell- BCC, FCC, HCP structures - short and long range order - effects of crystalline and amorphous structure on mechanical properties. Coordination number and radius ratio; theoretical density; simple problems - Polymorphism and allotropy Miller Indices: - crystal plane and direction (brief review) - Attributes of miller indices for slip system, brittleness of BCC, HCP and ductility of FCC - Modes of plastic deformation: -...

Oct 02, 2021 · The iron-iron carbide phase diagram is shown bel; Create an account to start this course today Used by over 30 million students worldwide Create an account Like this lesson Share. Explore our ...

"iron in pigs," as it comes from a blast furnace, iron that has been run while molten into a mold in sand, 1660s; see pig (n.2) + iron (n.).

The iron-iron carbide (Fe-Fe3C) phase diagram Figure 4-3 Iron-Iron Carbide Phase Diagram..4-10 Figure 4-4 Schematic Representation of Plain Carbon Steel (0.20% Carbon) When Heated Rapidly to the Temperature Shown..4-12 Figure 4-5 Schematic Representation of Transformations of Carbon Steel Iron - Wikipedia Iron and Steel Phase Diagram.

1705, "phase of the moon, particular recurrent appearance presented by the moon (or Mercury or Venus) at a particular time," back-formed as a singular from Modern Latin phases, plural of phasis, from Greek phasis "appearance" (of a star), "phase" (of the moon), from stem of phainein "to show, to make appear" (from PIE root *bha- (1) "to shine"). Latin singular phasis was used in English from 1660 for each of the aspects of the moon. General (non-lunar) sense of "aspect, appearance, stage of development at a particular time" is attested by 1841. Meaning "temporary difficult period" (especially in reference to adolescents) is attested from 1913.

"gradual, planned removal or elimination," 1958, from the verbal phrase (1954; see phase (v.)).

HT, Microstructures and Performance of Carbon and Alloy Steel s, January 24-25, 2022. January 24, 2022 - January 25, 2022 Virtual Classroom Instructor: Dana Medlin, Ph.D., P.E., FASM . Heat treated bar and forging steel s remain the major material for parts (such as shafts, gears, bearing, fasteners, oil country tubulars, aircraft landing gear, tools of all sorts, and many other applications ...

PPT - The Iron-Iron Carbide Phase Diagram PowerPoint ... Fe-C diagram; iron carbon diagram The Iron Carbon Phase Diagram; What is the difference between hypoeutectoid steel and ... Why is hypereutectoid steel harder and more brittle than ... What is the difference between hypoeutectoid steel and ... Repeat Problem 10.19 for a 0.9 wt % C ...

4.5 The Iron–Iron-carbide Phase Diagram and the Development of Microstructures in Steels 117 4.6 Cast Irons 119 4.7 Heat Treatment of Ferrous Alloys 121 4.8 Hardenability of Ferrous Alloys 123 4.9 Heat Treatment of Nonferrous Alloys and Stainless Steels 127 4.10 Case Hardening 129 4.11 Annealing 129 4.12 Heat-treating Furnaces and Equipment 133

Hey guys! I'm in a mechanical properties class over the summer and in class we were discussing the different properties of Iron as you add carbon to it, while looking over the iron - iron carbide phase diagram. This led to talks of the conductivity of various types of iron, and long story short, I'd like to find a graph of conductivity or resistivity with relation to carbon content. Anybody know where I can find one?

Answer: Iron loses its magnetic nature at 1043K and early investigators found that this loss is due to phase transformation and named the paramagnetic iron( above 1043K) as beta iron.Later it was found that the loss in magnetic nature is not because of phase transformation and they removed the be...

Cast Iron is considered the most widely used metal-matrix composite from the 1920s. Follow microstructural development in Cast Iron types to learn about graphite nucleation mechanism, lediburite formation, and eutectic and eutectoid reactions within cast iron.. Cast Iron is being used in a wide area of industry i.e. boilers, water conduit pipes in Oil and Gas Industry.

Fe C Phase Diagram. fe c phase diagram. this is part three in a series of screencasts about phase diagrams. this video introduces major features of the fe fe3c phase diagram, steel classification, and this sceencast is part four of our series about phase diagrams. this sceencast is focused on addressing issues students have with iron iron carbide (steel) this video tells us the information ...

4.5 The Iron—Iron-carbide Phase Diagram and the Development of Microstructures in Steels 108. 4.6 Cast Irons 109. 4.7 Heat Treatment of Ferrous Alloys 111. 4.8 Hardenability of Ferrous Alloys 113. 4.9 Heat Treatment of Nonferrous Alloys and Stainless Steels 117. 4.10 Case Hardening 119. 4.11 Annealing 121. 4.12 Heat-treating Furnaces and ...

The main evolution stages of the phase diagram of Fe-C in the carbide region (on the right from the cementite line) is a recently discussed theoretical topic that has been considered. It has been determined that previously isolated ε-Fe 2 C, χ-Fe 5 C 2, and g-Fe 7 C 3 carbides (except for cementite Θ-Fe 3 C) are nonstoichiometric compounds.

Preface: IANAMS (I am not a material scientist), I'm basing this off of my entirely empirical and forum-based understanding of these diagrams, and am hoping that this will help others understand (roughly) hot to read them. I linked a TTT diagram in a response to a question about how to heat-treat a steel on another post, and it inspired me to come up with this as a follow-up. I'm writing this in bits and pieces, so it may be slightly disorganized, but hopefully it's helpful to someone. A lot of...

The Iron - Iron Carbide (Fe-Fe. 3. C) Phase Diagram ... C (iron carbide or cementite) ... pearlite, layered structure of two phases: α-ferrite and cementite.67 pages

The phase equilibria of cemented carbides are characterized by the existence of a two phase region between the carbide phase and the binder metal phase Fig. Iron-Iron Carbide Phase Diagram. Realtek audio drivers for intel 9.

The iron-iron carbide (Fe-Fe 3 C) phase diagram.The percentage of carbon present and the temperature define the phase of the iron carbon alloy and therefore its physical characteristics and mechanical properties. The percentage of carbon determines the type of the ferrous alloy: iron, steel or cast iron.

(10 points) (c) Write the reactions for the three invariant reactions that take place in the Fe-Fe 3C phase diagram. (10 points) a) Fe-Fe 3 C phase diagram is not a true equilibrium phase diagram because of un- stability of iron carbide (Fe 3 C) compound. Under certain conditions Fe 3C will decompose into more stable phase s of iron and graphite. Of course, the carbon in cast iron can also be ...

compound formed by combination of carbon and another element, 1848, from carb-, combining form of carbon + chemical suffix -ide. The earlier word was carburet.

To achieve consistency in the material microstructure, this technique involves homogenization or grain refining. To obtain a homogeneous austenitic phase, the material is heated to a temperature above the upper critical line of the iron carbide phase diagram. After that, a cooling phase in mildly agitated air is used to create ferrite. Annealing

The Iron Carbon Phase Diagram · A : The temperature where iron looses its magnetism (so-called Curie temperature). · A : The boundary between the γ austenite ...

Lecture 1_Review of the Iron-Iron Carbide Phase diagram.pdf. University of Namibia. ECONOMICS EMA3572. Austenite; University of Namibia • ECONOMICS EMA3572. Lecture 1_Review of the Iron-Iron Carbide Phase diagram.pdf. 40. Lecture 06_Equilibrium phase diagrams_2020_D.pdf. University of Namibia. MINING ENG 19BMNE.

PPT - Phase Diagrams Binary Eutectoid Systems Iron-Iron-Carbide Phase Diagram Steels and Cast Iron PowerPoint Presentation - ID:1705700.

![Iron Carbon Equilibrium Diagram [PDF|TXT]](https://html.pdfcookie.com/02/2019/12/19/mlxz39d18327/bg2.jpg)

![Iron–iron carbide phase diagram [6, 7]. | Download Scientific Diagram](https://www.researchgate.net/profile/Shamail-Ahmed/publication/281806061/figure/download/fig1/AS:522846623498240@1501667757641/Iron-iron-carbide-phase-diagram-6-7.png)

![The iron-carbon phase diagram [46]. | Download Scientific Diagram](https://www.researchgate.net/profile/Muna-Abbass/publication/293333803/figure/fig2/AS:669013386469398@1536516629671/Figure-2-11-The-iron-carbon-phase-diagram-46.png)

![Iron-carbon phase diagram [SubsTech]](https://www.substech.com/dokuwiki/lib/exe/fetch.php?w=&h=&cache=cache&media=iron-carbon_diagram.png)

0 Response to "39 iron carbide phase diagram"

Post a Comment