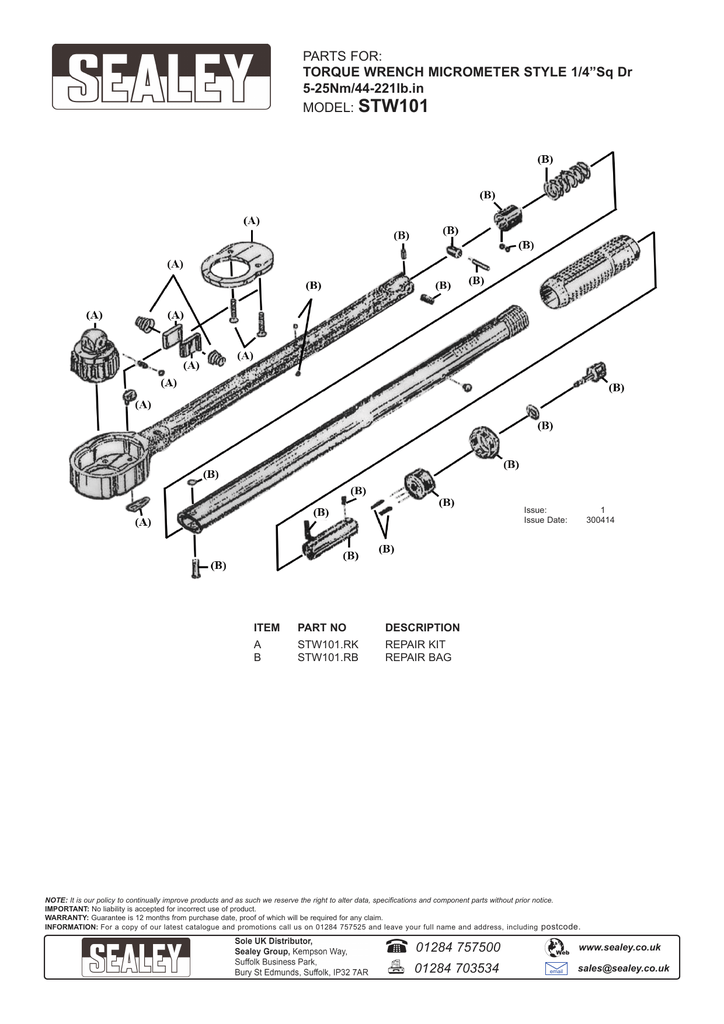

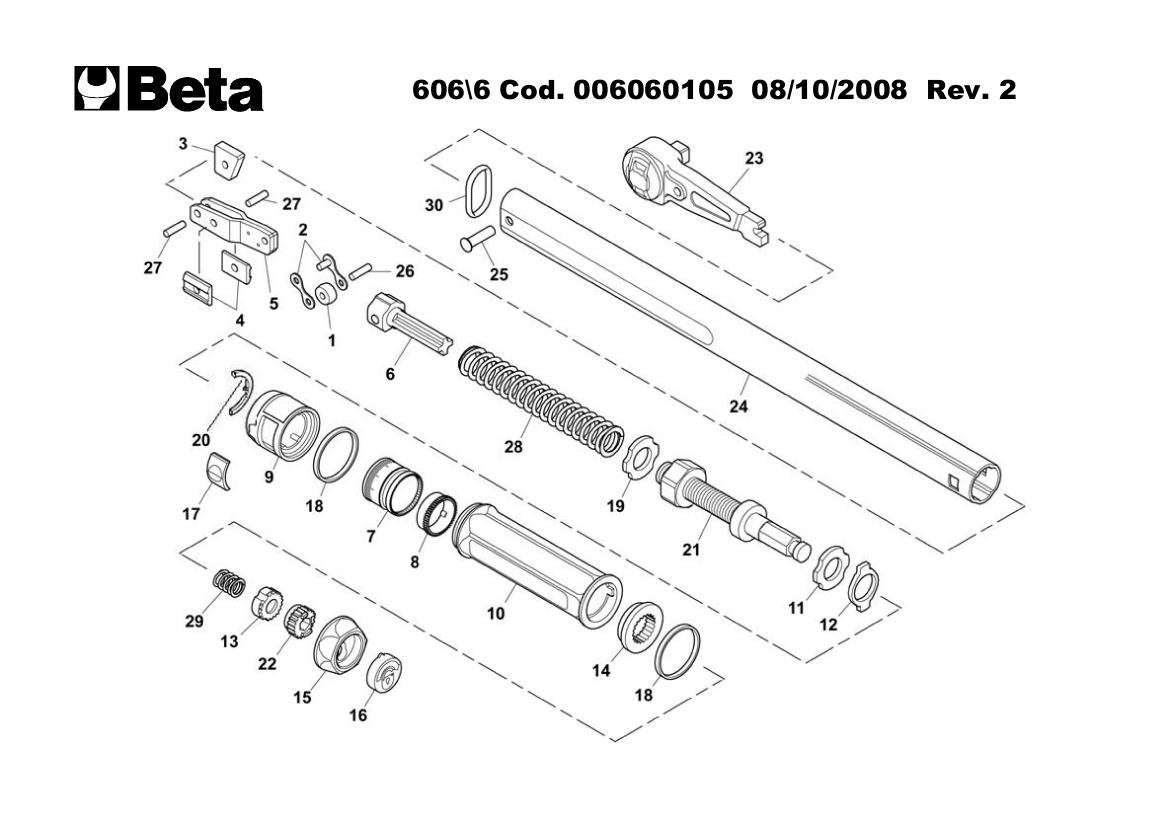

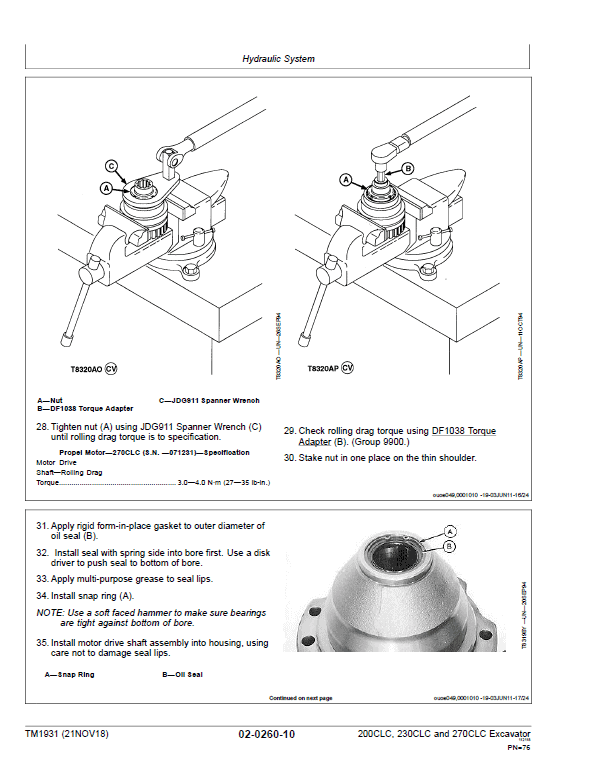

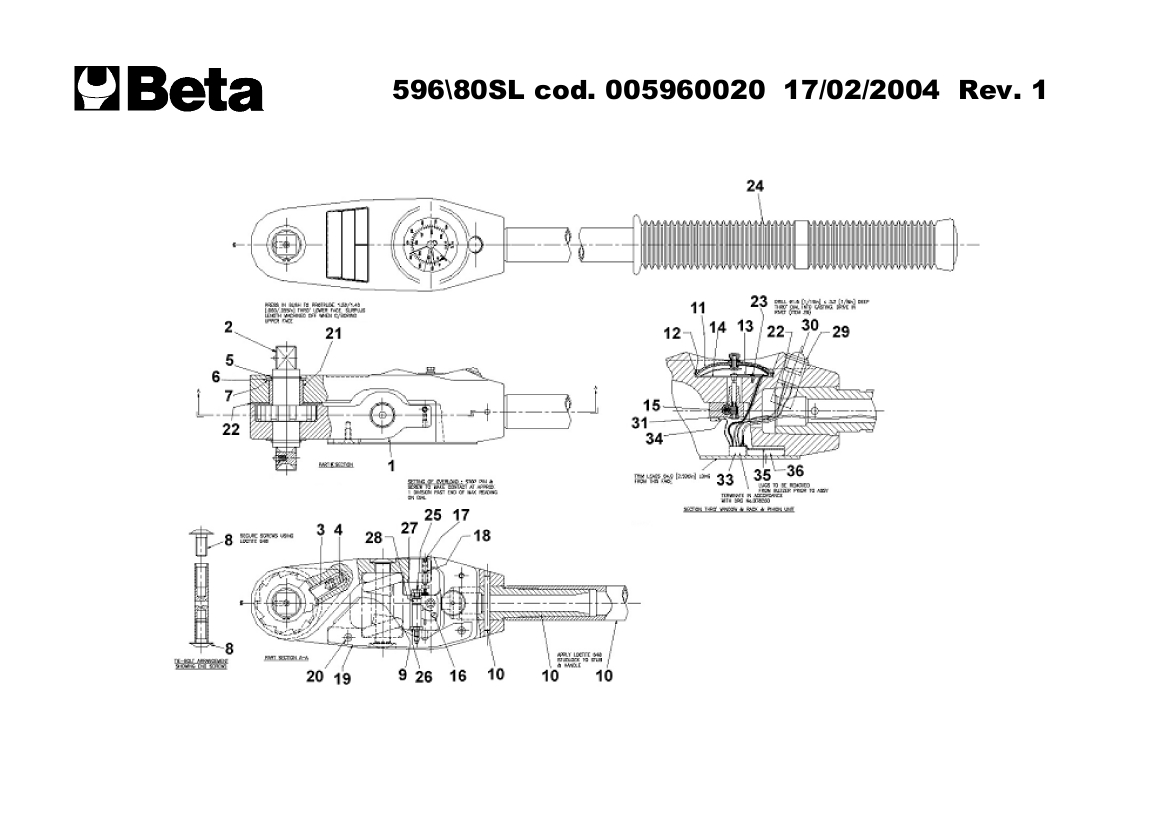

41 torque wrench parts diagram

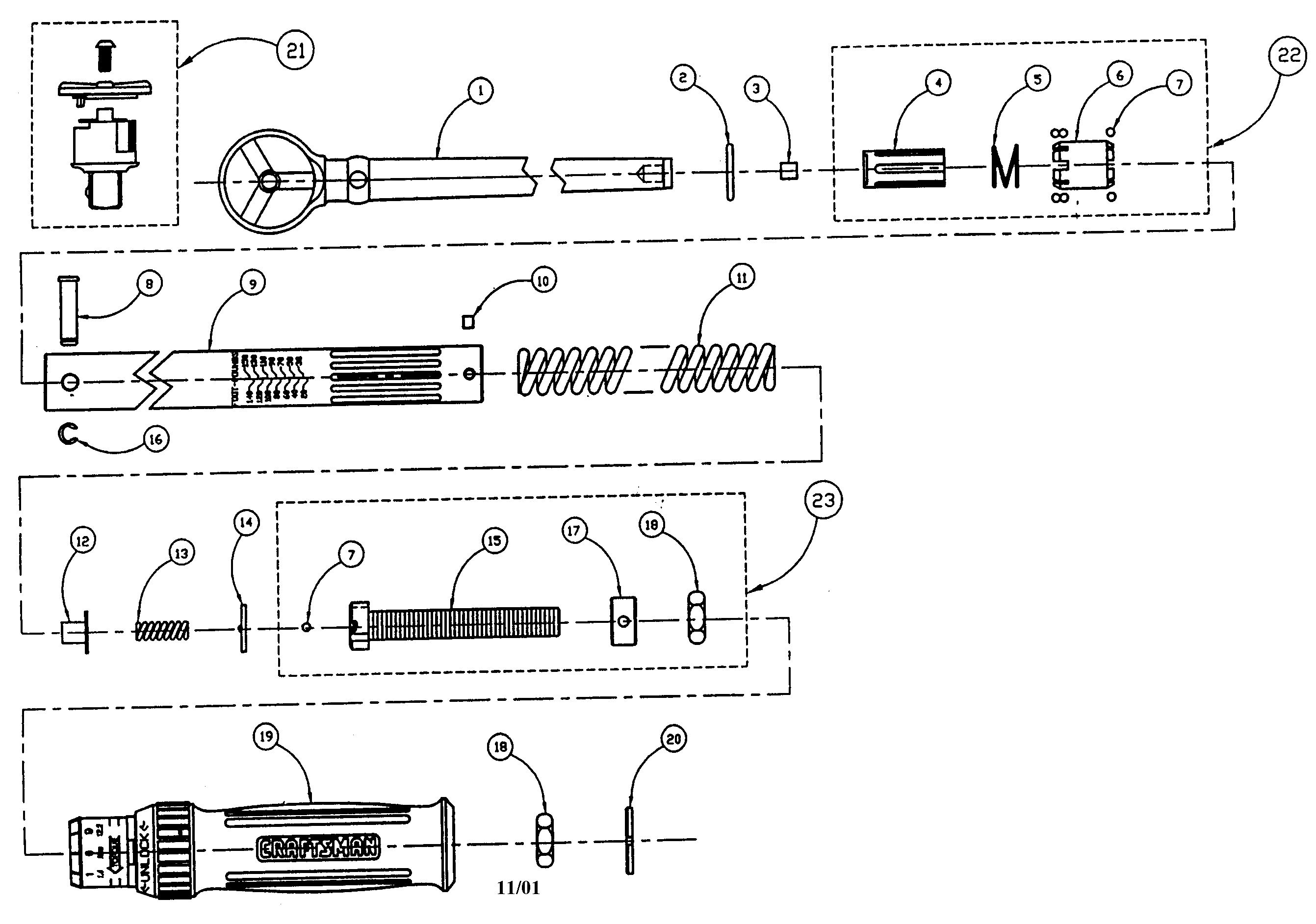

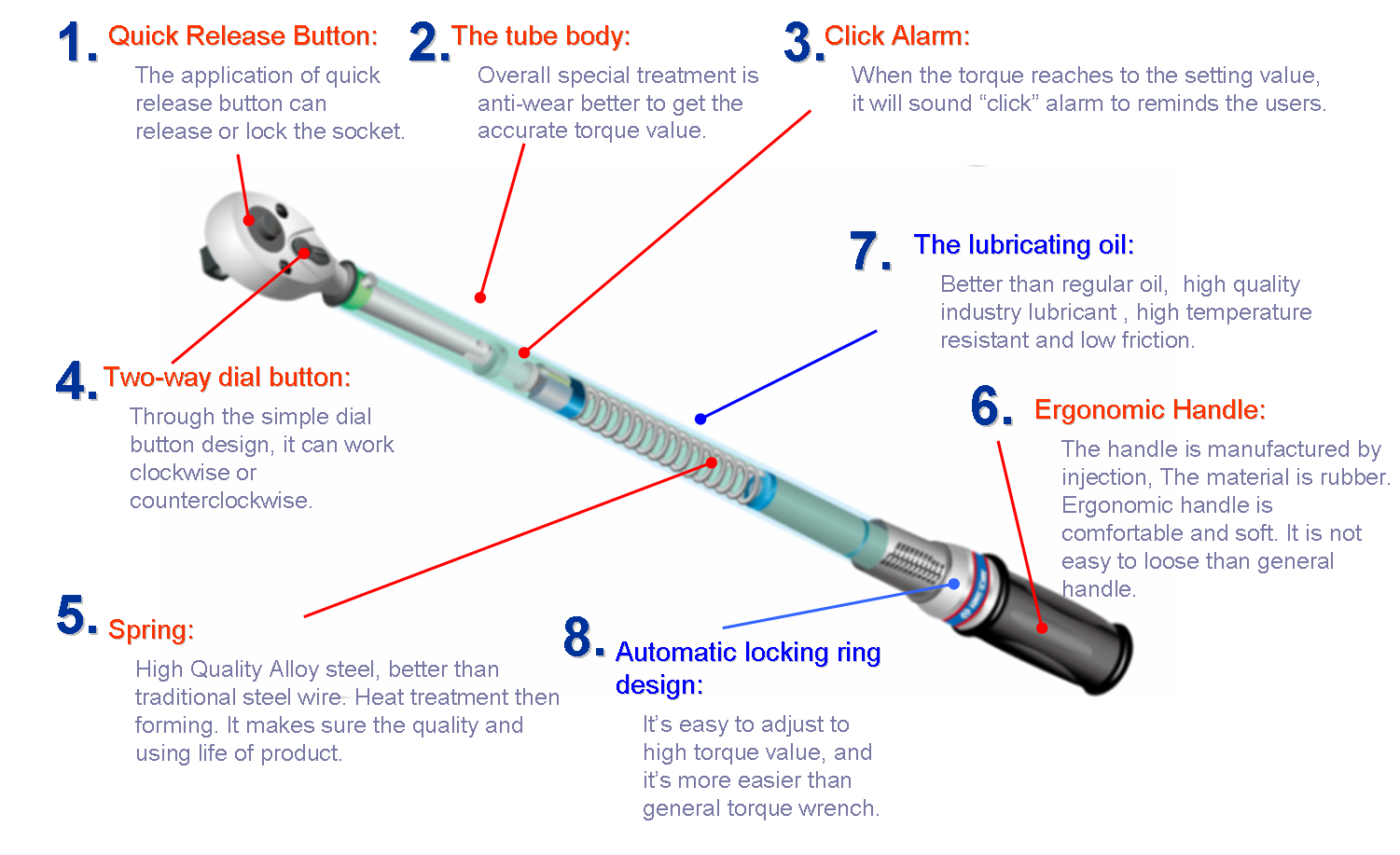

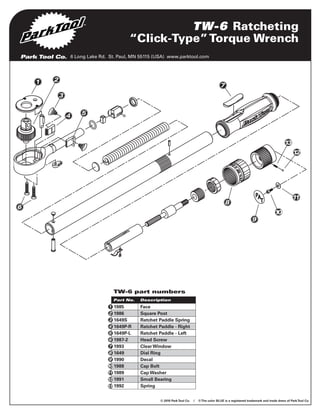

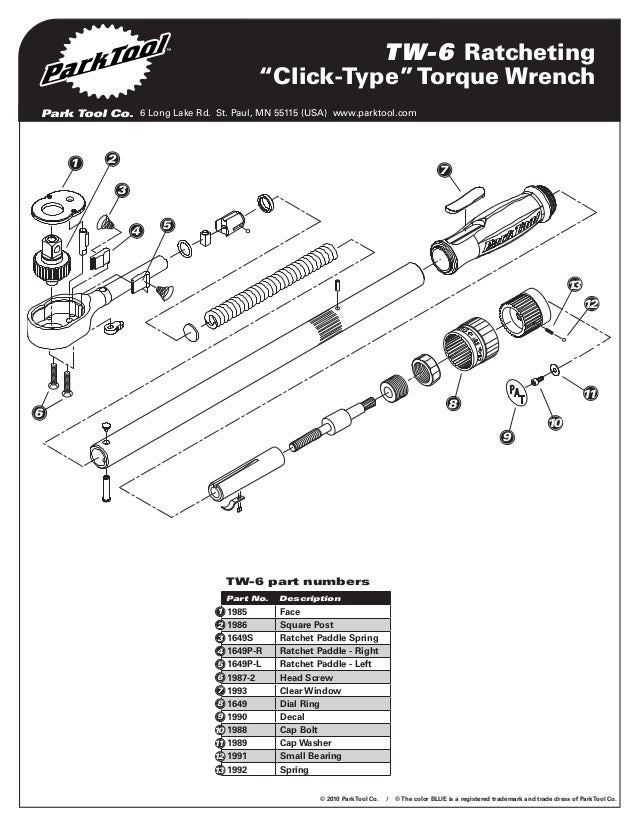

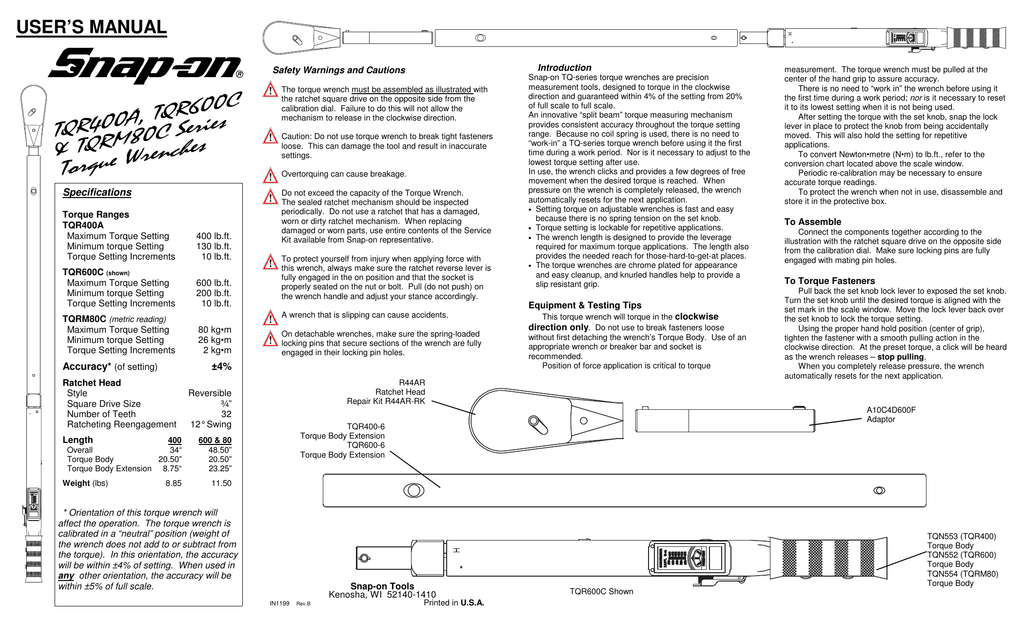

This is a dual-range torque wrench marked with foot pounds ( .-lb.) and Newton meters (Nm) on opposite sides of handle. The torque scale is marked on the handle body with more NOTE: Exploded view diagram provided for illustration purposes only. Do not disassemble any part of torque wrench. A torque wrench is a measuring tool that is. always employed when the bolted joint of a. product affects its quality and/or safety. torque wrench, this click point is essentially. determined by tactile feedback, both during. calibration and in use. Another problem for the measurement.

This torque wrench is designed for manual tightening of threaded ... case, or any part replaced, the wrench must be immediately re-calibrated prior to next ...8 pages

Torque wrench parts diagram

E xploded view diagram provided for illustration purposes only. Do not disassemble any part of torque wrench. There are no user serviceable parts on or inside ...4 pages The basics of torque and torque wrench use on bicycles, including a table of various torque spec recommendations. Each fastener is designed for a certain range of tension. Too much tightening will deform the threads or the parts. Too little preload will mean the fastener will loosen with use. * A torque wrench for this configuration is not currently in stock. Please call Sales @ 1-800-715-4396 for a quote. 1 The material the connector body is comprised of. 2 Minimum recommended torque value for a successful connection per applicable MIL-STD or industry standard.

Torque wrench parts diagram. The Electronic Torque Wrench is a precision hand tool designed to permit accurate manual tightening of threaded fasteners. The tool is designed around a conventional ratchet wrench with a self-contained microprocessor built into the wrench handle. The control housing contains the operating controls... If you are looking for a torque wrench that’s loaded with functionality, then the Tekton 24355 1/2-inch drive click torque wrench is an excellent choice. Runner-up EPAuto 1/2-inch Drive Click Torque Wrench, 10~150 ft./lb., 13.6 ~ 203.5 N/m 23/06/2021 · Unlike Philips or Pozidriv screwdrivers, even on power devices with high driving speeds, too much torque can be transferred with no chance of equipment slipping, which makes it safer to use. Torx-type screwdrivers come in a variety of sizes and use a numbering system such as T8, T10, T15, T25, etc. to determine the tip size. A torque wrench is an invaluable tool for automotive work. Most commonly used for tightening wheel lug nuts to exact specifications, it can be used for many auto repair and maintenance tasks. In this article, we'll go over what a torque wrench is, the four different types of torque wrenches, and how...

Need to fix your 44595 Torque Wrench? Use our part lists, interactive diagrams, accessories and expert repair advice to make your repairs easy. Craftsman 44595 Torque Wrench Parts. File:Torque wrench extension 1.png. From Wikimedia Commons, the free media repository. Jump to navigation Jump to search. English: A diagram aimed at illustrating the "extensions" part of the English wikipedia entry for torque wrench. A torque wrench is a specialized tool — nothing else in your toolbox can take its place. Treat your torque wrench right and it will provide accurate After using your torque wrench, always dial it back to zero. Leaving it set means the spring mechanism inside it remains loaded, taxing and wearing out... Pneumatic Torque wrenches are the preferred torquing method to achieve productivity with less man-power. Powermaster Pneumatic torque wrenches offer the reliable and dependable solution for the torquing and un-torquing of heavy duty bolts and nuts at various industries where speed, power...

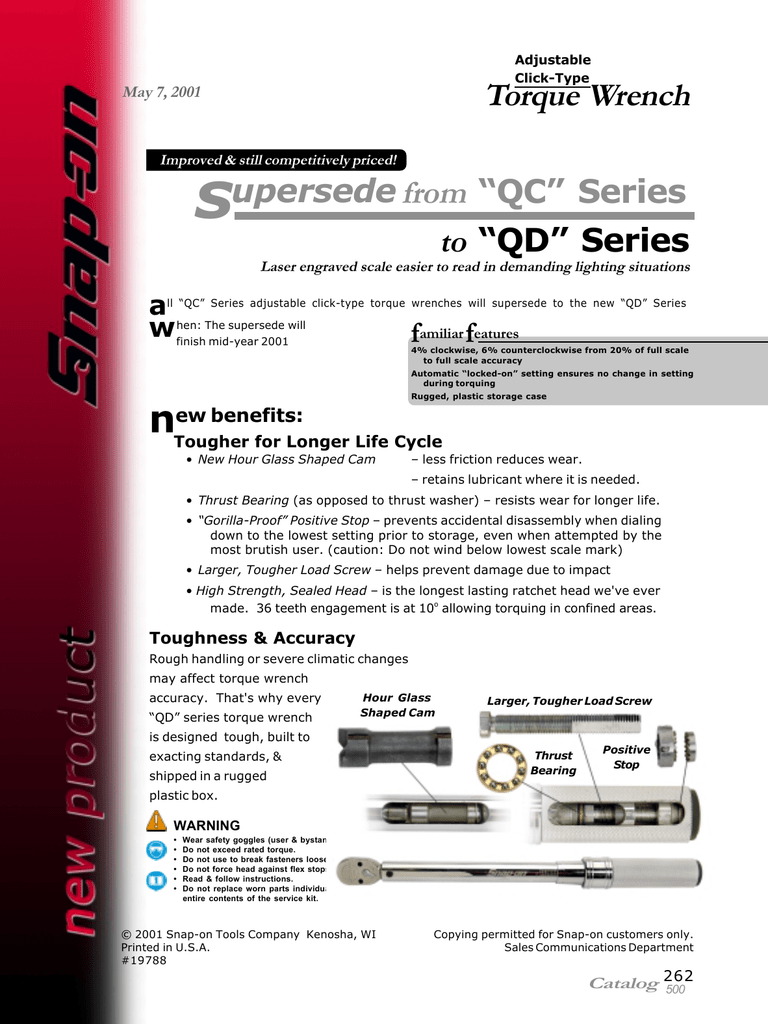

Torque wrench. Repair, maintenance. And troubleshooting. Manual. Suggested price $35.00 part number: 21-201-01 issued Adjustment Tool Part Numbers Troubleshooting Micrometer Adjustable Torque Wrench Troubleshooting Matrix. 13 14 15/17 17 17 18/23 18/21 21/23... How Does a Torque Wrench Work? A torque wrench is a calibrated tool for applying a known A torque wrench indicates how much force you are applying to a fastener with a deflection beam or a You can usually buy a beam style torque wrench for less than $30 in most auto parts stores or online. Smart torque wrenches 1,5-30N.M. Accuracy: - Torque: ± 2% Fixed ratcheting head BlueTooth Connectivity Data collection and recording Haptic Feedback in 3 stages, LED light indicator Measuring unit: N.m, kg.cm, lbf.ft, lbf.in. Li-ion battery 3.7V 2.6Ah, 4h charging time Suppli ... TQ Series Torque Wrenches. • Durable split beam style torque wrench • No need to zero after use • 4% accurate in Torque wrench square drive axis with vertical orientation. In all other positions, guaranteed accuracy is ±5 An out of calibration torque wrench can cause part of tool breakage. •

Electronic Torque Wrenches TorcoTronic. 312. Torque calibration analyser DREMOTEST E 314. › All parts incorporated in the production process - from steel to the. smallest spring - are controlled while all manufacturing and work steps are subject to stringent quality controls.

03/01/2022 · Here in this article, we will talk about the common Parts of a Hammer Diagram so that next time you use a hammer you know what you are doing with that. Before, you know about the differences you need to know that there are different types of hammers also.

A torque wrench is a tool used to measure the amount of torque that is being applied to bolts and nuts. Specific bolts must be inserted with circular force. The torque wrench can be identified by its strong similarities to a ratchet, although it has a longer handle.

Knowing the level of torque you're applying to a nut is essential for the stability of a piece of machinery or structure. If you use too little torque, the nut may not be secure, and if you apply 2 Understanding the Numbers on a Beam or Dial Torque Wrench. 3 Using a Digital-Read Torque Wrench.

How To Use a Torque Wrench. Смотреть позже. Поделиться.

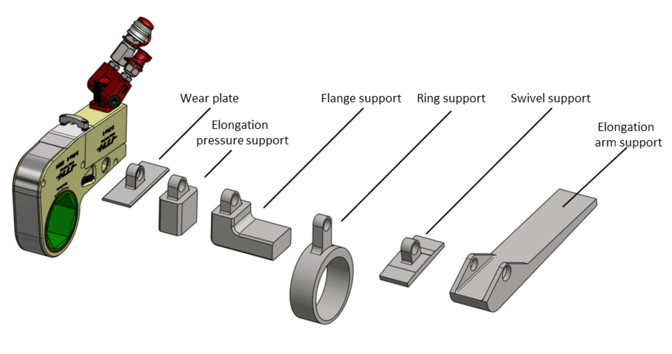

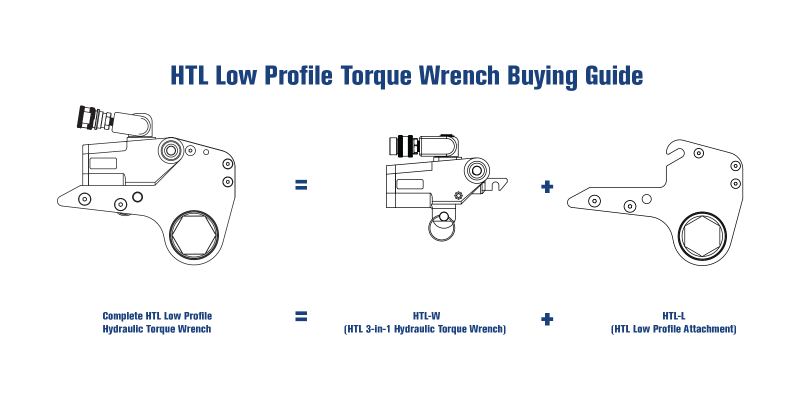

The hydraulic torque wrench is a power tool. Read all instructions, warnings and precautions before every operation. ▲ CAUTION Keep all hydraulic torque wrench components away from excessive heat, flame, moving machine parts, sharp edges and chemicals.

If you don't have a torque wrench available - or if you want to check the readings of the one you have - it is easy to improvise by using a standard wrench and a scale as indicated in the figure above. The moment - or torque - can be calculated. T = F a (1).

Torque wrenches are available in certain torque spans which is why you may need more than one. Here I have a 3/8" drive inch pound torque wrench Now to set the torque wrench, they should have some form of a lock which needs to be disengages, then rotate. This vehicle which is a 1998 Ford...

This torque wrench is economical, offers a broad torque range, and is made from superb construction. The wrench measures 25" long and is reinforced with The ratchet head drives in forward and reverse and measures torque in a clockwise direction. The all-steel construction contains no plastic parts that...

The shaft or shank is commonly made of strong steel to ensure that bending or twisting deformation does not occur when applying force. The shaft will be rounded or hexagonal to allow a spanner or wrench to be used to apply increased torque. The shaft is generally different colouration and material to the drive tip which can be interchangeable.

Torque wrench parts. Our top categoriesView more categories.

Work efficiently with our selection of professional-grade torque wrenches. Shop micro, dial, preset, interchangeable head, and other torque wrenches here.

Product Description: Enerpac hydraulic torque wrenches are double acting hand-controlled tools designed to tighten and The torque wrench must be properly positioned manually to make sure that the reaction force is safely transmitted via there reaction arm and not via other torque wrench parts.

Below is my "best torque wrench" recommendation for motorcycles and dirt bikes. While I wish that there was a one-size-fits-all torque wrench, there Picking a torque wrench based on what you need it for, or plan on using it for is the best approach. In a perfect world, you'd actually have two or three...

A torque wrench is only useful if accurate. For this, I acquired a digital torque wrench tester to test peak loads between 1-10Nm. This is the only digital torque wrench on test, and also the most accurate. Without mechanical clicking parts, it proved immune to torque reading inconsistencies.

Quality replacement power tool parts at the best price. Industrial Tool and Supply .com Find a full assortment of genuine Makita and DeWalt replacement parts for your power tools. Order online or call 435-753-4256. At Industrial Tool and Supply, our customers come first.

13/06/2000 · Torque (lbft) Torque (kgm) Drive shaft coupling U bolts (rubber cross inner joints) 8 to 12: 1.11 to 1.66: Drive shaft nut (front hub, drum brakes). Continue tightening until next split pin slot aligns. Do not slacken off until the next slot aligns! 60: 8.3: Tie rod to front sub-frame: 20 to 24: 2.8 to 3.3: Tie rod to lower front suspension ...

Torque Wrench Torque Screwdriver Power Torque Tool. Torque Gauge Torque Meter Bolt Tension Meter. New Traceability System Diagram. Torque Standard Machine Designated Secondary Standard Equipment. torque wrench shaped sensor part (torque converter) provided with a lever.

The working torque of the impact wrench is 230 ft.-lbs. Make sure that the nut or bolt you are using the tool to tighten can withstand the rated torque. 1.Tighten the nut as far as you can by hand. 2.Place the socket on the nut. Press the REVERSE valve forward so it protrudes out the front of the Housing.

This is the Head Bolt Torque Sequence (Pattern) for the Small Blocks, Mouse Motors or what ever you might lovingly call this motor. I have not had a …

This is the Head Bolt Torque Sequence (Pattern) for the Mark IV Big Blocks, Rat Motors or what ever you might lovingly call the motor. I am an old timer and had a 1969 SS 396 that subsequently

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw.It is usually in the form of a socket wrench with special internal mechanisms.. A torque wrench is used where the tightness of screws and bolts is crucial. It allows the operator to set the torque applied to the fastener so it can be matched to the specifications for a particular …

* A torque wrench for this configuration is not currently in stock. Please call Sales @ 1-800-715-4396 for a quote. 1 The material the connector body is comprised of. 2 Minimum recommended torque value for a successful connection per applicable MIL-STD or industry standard.

The basics of torque and torque wrench use on bicycles, including a table of various torque spec recommendations. Each fastener is designed for a certain range of tension. Too much tightening will deform the threads or the parts. Too little preload will mean the fastener will loosen with use.

E xploded view diagram provided for illustration purposes only. Do not disassemble any part of torque wrench. There are no user serviceable parts on or inside ...4 pages

0 Response to "41 torque wrench parts diagram"

Post a Comment