40 phase diagram of steel

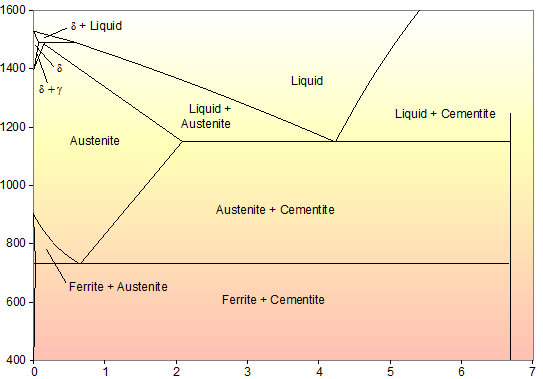

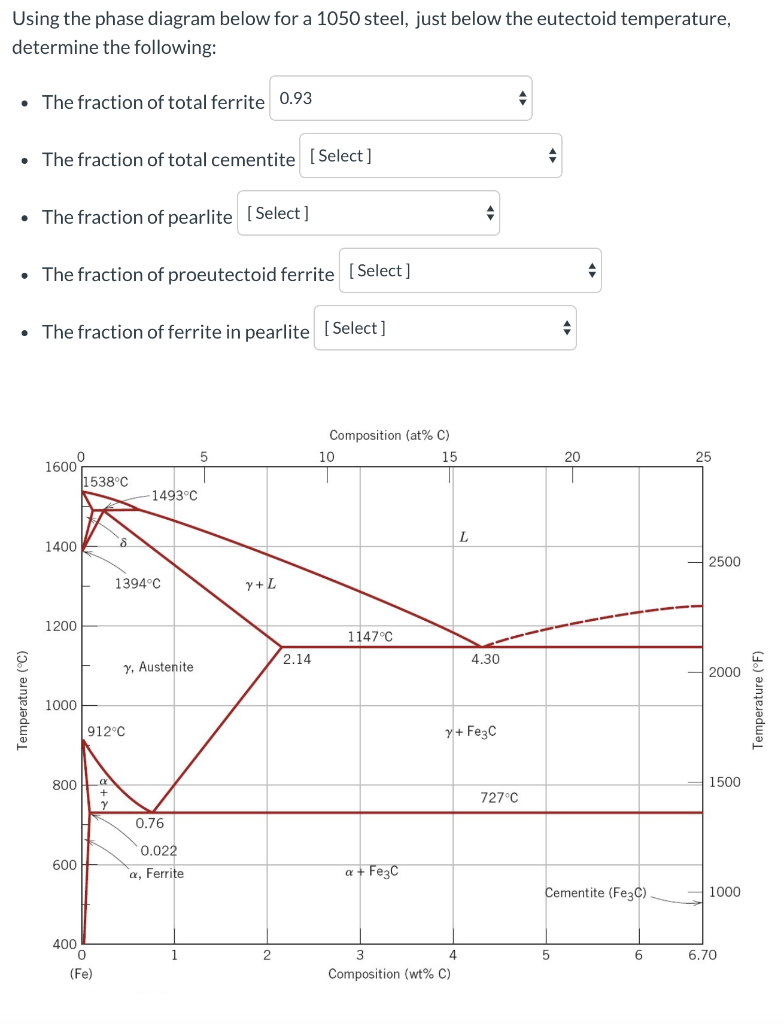

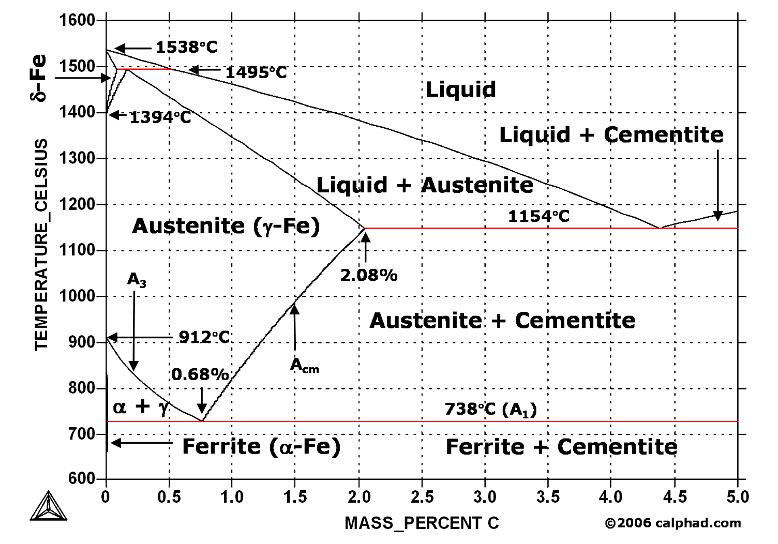

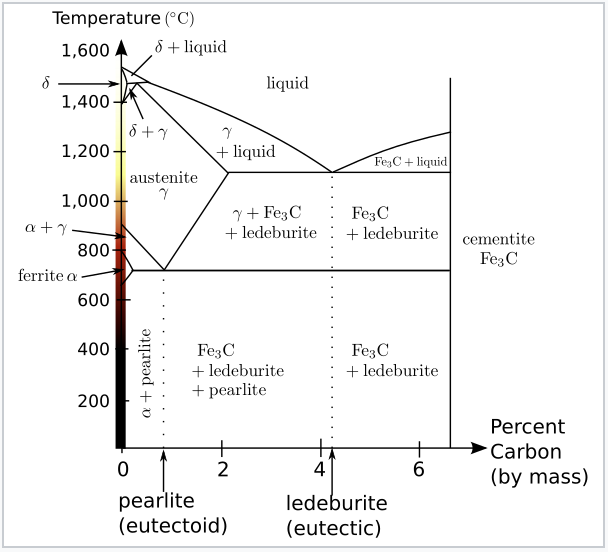

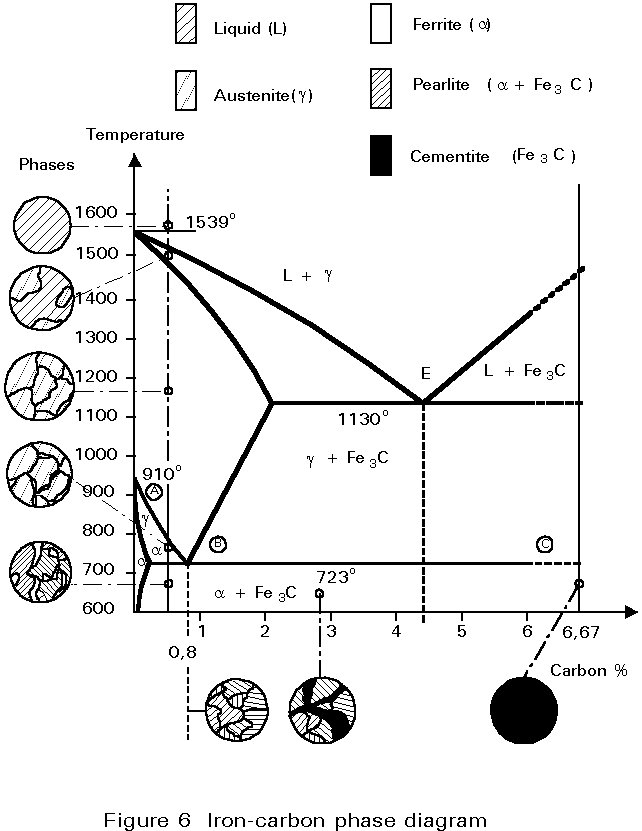

Fundamentals of Carbon Steel Part 1 - Phases ... - LFF Group Fundamentals of Carbon Steel Part 1 - Phases & Microstructures. Carbon steel is fundamentally an alloy of iron and carbon. At room temperature, carbon is virtually insoluble in iron; the maximum solubility of carbon is approximately 0.008 wt%. Below 0.008 wt%, the structure will be made up entirely of ferrite, which has a body-centred cubic ... Phase Diagram of Steel - Metallurgy for Dummies Phase Diagram of Steel Fe-Fe 3 C Phase Diagram, Materials Science and Metallurgy , 4th ed., Pollack, Prentice-Hall, 1988 Figure above shows the equilibrium diagram for combinations of carbon in a solid solution of iron. The diagram shows iron and carbons combined to form Fe-Fe3C at the 6.67%C end of the diagram.

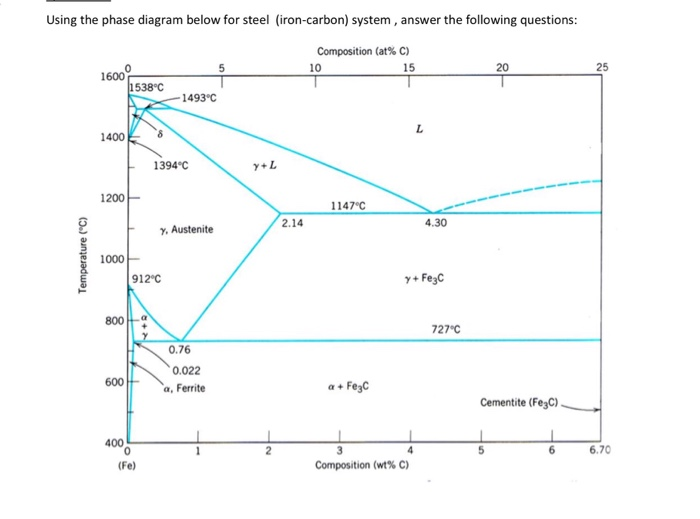

Carbon Steels and the Iron-Carbon Phase Diagram - IspatGuru 06-03-2016 · Because this temperature-composition point lies in the central region, the steel must be a mixture of ferrite and austenite, two examples of which are shown at the left side of the Fe-C phase diagram. The portion of the phase diagram in hypo- eutectoid region is shown in Fig 3. It provides information about the composition of the two phases.

Phase diagram of steel

Phase Diagram - Industrial Metallurgists 14-08-2021 · Iron-Carbon Phase Diagram An example of a commonly used phase diagram is the iron-carbon phase diagram, which is used to understand the phases present in steel. The amount of carbon present in an iron-carbon alloy, in weight percent, is plotted on the x-axis and temperature is plotted on the y-axis. Time Temperature Transformation (TTT) Diagrams Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath (Figs. 1- TTT Diagram Basic - TTT diagram for steel, eutectoid steel Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.

Phase diagram of steel. 3 Phase Induction Motor Definition And Working Principle 24-02-2012 · An electrical motor is an electromechanical device that converts electrical energy into mechanical energy. In the case of three-phase AC (Alternating Current) operation, the most widely used motor is a 3 phase induction motor, as this type of motor does not require an additional starting device.These types of motors are known as self-starting induction motors. Phase diagram - Wikipedia A phase diagram for a binary system displaying an eutectic point. One type of phase diagram plots temperature against the relative concentrations of two substances in a binary mixture called a binary phase diagram, as shown at right. Such a mixture can be either a solid solution, eutectic or peritectic, among others. Steel - Wikipedia Steel is an alloy made up of iron with typically a few tenths of a percent of carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant need typically an additional 11% chromium.Because of its high tensile strength and low cost, steel is used in buildings ... 4140 Steel Phase Diagram - wiringall.com 4140 Steel Phase Diagram HW meets AISI standards and has improved hardenability and strength in heavier cross-sections. Alloy Description. TimkenSteel's HW grade is a fine-grained, low-alloy steel that offers optimum CCT/IT phase transformations. Calculation of the Equilibrium Phase Diagram for Steel. Summary. 3.

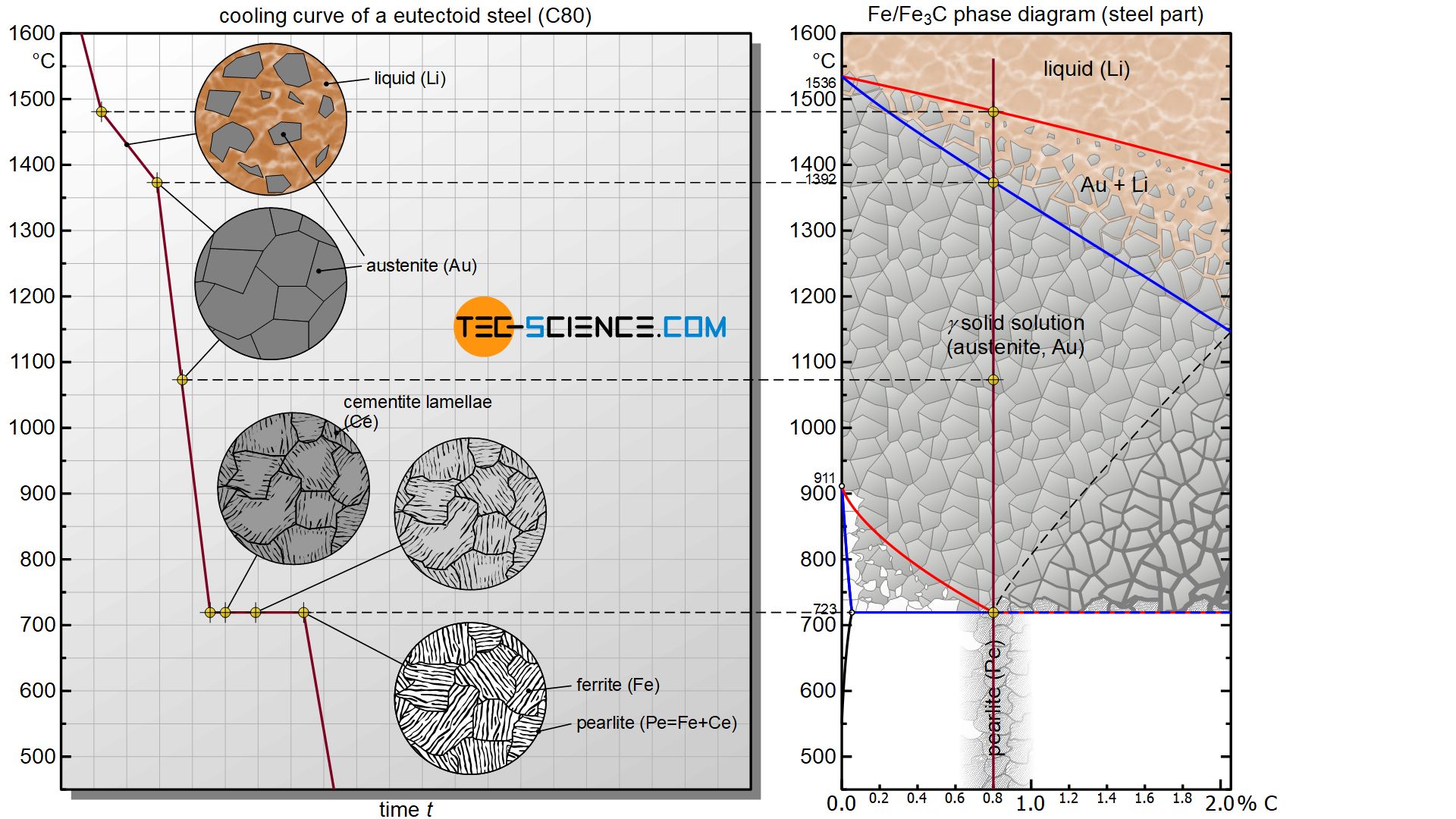

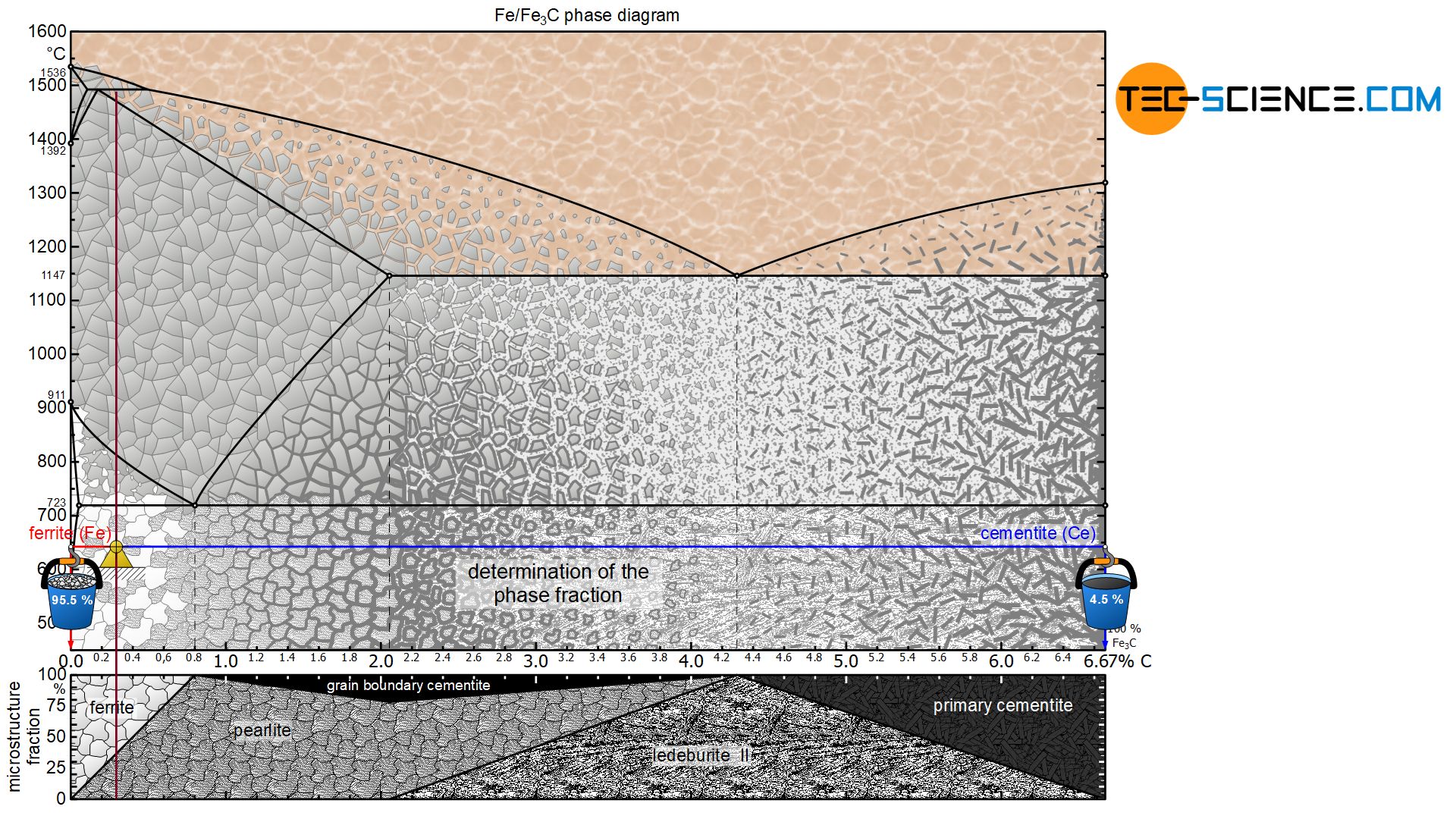

Summary of the phase transformations of steel - tec-science The actual solidification process in steels takes place independently of the carbon content as in a solid solution alloy. This is shown in the phase diagram as a typical lenticular region between the liquidus and the solidus line. The carbon is completely soluble in the face-centered cubic γ-iron lattice structure immediately after solidification. Comparison of phase transformations in steels - tec-science Phase transformations in steels can be compared to those of solid solutions (completely soluble) and crystal mixtures (completely insoluble). The figure below shows steel part of the iron-carbon phase diagram of the metastable system.A closer look at the transformation lines below the solidus line shows the horizontal "K" typical of alloys, whose components are insoluble in one another. Metallurgy of Stell & Phase Diagrams Flashcards | Quizlet Name 4 steel types based on microstructure. Ferritic. Austenitic. Pearlitic. Duplex structure (e.g., Austentic-Ferritic) Give the three ways that carbon uses to strengthen steel. - C can dissolve in Fe: small C atoms can fit into the gaps of larger atoms of Fe. And so they do this forming a solid solution. TTT Diagram of steel in Material science - Materials Today TTT diagram of steel is valid only for one single composition. With varying compositions, plots, and curve also vary. This diagram is only understood if steel immediately cools down from austenitizing temperature to transformation temperature and held constant during the completion of transformation.

PDF LAB IV Heat Treatment of Steel Heat Treatment of Steel STUDY QUESTIONS: 1. In terms of heat treatment and the development of microstructure, what are two major limitations of the iron-iron carbide phase diagram? 2. Consider the Iron-Carbon Phase Diagram shown in your textbook. For alloys containing 0.5%C, 0.8%C and 1% C, which have been slowly cooled from the PDF Lecture 19: Eutectoid Transformation in Steels: a typical ... Martensite is not shown in the equilibrium phase diagram of the iron-carbon system because it is a metastable phase, the kinetic product of rapid cooling of steel containing sufficient carbon. • Bainite: first described by E. S. Davenport and Edgar Bain, is a phase that exists in steel microstructures after certain heat treatments. The steel phase diagram - YouTube No phase diagram is more important to materials scientists than the Fe-C phase diagram because it allows us to explain many of the different types of steels.... Bill Lawrence Pickups - Bill and Becky Wilde Pickups 01-09-2019 · Wilde Bill Lawrence Noise-free Series The L280 series for Strat and Tele was launched in 1995. It has been almost 25 years and is still one of the best noise-free...

Metallography of Steels - University of Cambridge The phase diagram illustrates the domains in which particular phases or combinations of phases are stable, and contains information about their equilibrium compositions. Equilibrium phase fractions can also be estimated from a knowledge of the carbon concentration of the steel and an application of the lever rule.

Database of Steel Transformation Diagrams - AISI Steels Database of Steel Transformation Diagrams Alphabetical Index Chemical Composition Keyword Search AFNOR Steels AISI/SAE Steels BS Steels DIN Steels Wr.Nr. (Mat.No.) Steels Calculated Diagrams CCT Diagrams TTA Diagrams TTE Diagrams TTT Diagrams TTP Diagrams TTS Diagrams Alloy Steels Carbon Steels Carburizing Steels

The questions in the following question all pertain ... Transcribed image text: The questions in the following question all pertain to the iron-carbon phase diagram, shown below. Composition (at% C) 10 15 0 5 20 25 1600 1538°C - 1493°C L 1400 8 2500 1394°C 7+L 1200 1147°C 2.14 4.30 y, Austenite 2000 1000 Temperature (°F) 912°C y + Fezc 800 1500 a + Y 727°C 0.76 0.022 600 a, Ferrite a + Fezc Cementite (Fe3C) 1000 400 0 (Fe) 6 6.70 3 4 ...

PDF Fundamentals of the Heat Treating of Steel phase diagrams. As a rule, percentages of two principal elements are shown on the horizontal axis of a figure, while temperature variation is shown on the vertical axis. However, the constitutional diagram of a pure metal is a simple vertical line. The constitutional diagram for commer-cially pure iron is presented in Fig. 1.

Ferritic stainless steel - Wikipedia To qualify as stainless steel, Fe-base alloys must contain at least 10.5%Cr. The iron-chromium phase diagram shows that up to about 13%Cr, the steel undergoes successive transformations upon cooling from the liquid phase from ferritic α phase to austenitic γ phase and back to α.

PDF 10. Phase diagrams X. PHASE DIAGRAMS 10-1 INTRODUCTION Take a small sample of almost any material, say a piece of steel, brass or bronze, polish the surface and place it under an optical microscope and you will see crystalline grains of different size shape and composition. For some materials, these grains are

Making low-alloyed steel strong and tough by designing a dual ... Moreover, the unique dual-phase layered structure also renders the UFG F/M layered steel dramatic toughness enhancement both at room and cryogenic temperature compared with the Q&T steel, as shown in Fig. 5b. The Q&T steel exhibits a typical ductile-to-brittle transition in Charpy V-notch impact tests at temperatures from 50° to –130 °C ...

Iron-Carbon Equilibrium Diagram | Metallurgy Iron-Cementite diagram is not a true equilibrium diagram, since equilibrium means no change of phase with time, however long it may be. Graphite is more stable form of carbon. Cementite is a metastable phase, which decomposes to graphite if given long periods of time.

Austenitic Stainless Steels - ASM International anywhere in the portion of the Delong diagram labeled austenite shown in Fig. 1 (Ref 1). This diagram was designed to show which phases are present in alloys in the as-solidified condition, such as found in welds. Thus it also applies to castings and continuously cast products. As a practical matter of castability, the composition

The Al-Si Phase Diagram - Buehler, an ITW Company The Al-Si Phase Diagram The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions.

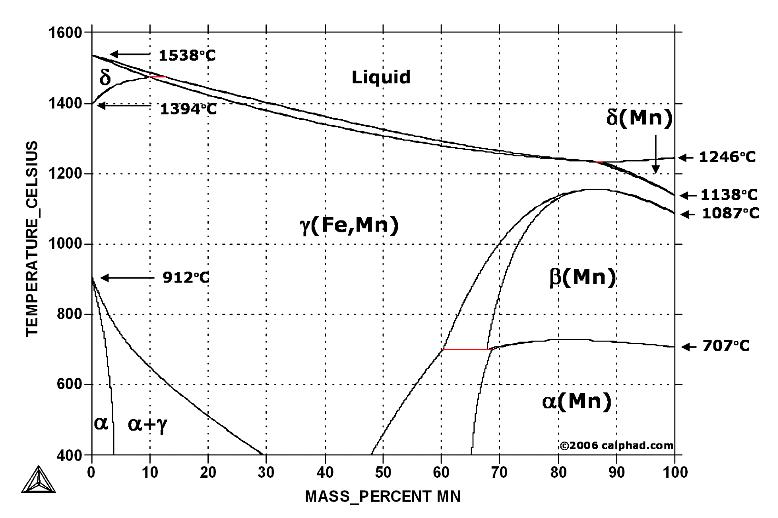

Iron-Carbon Phase Diagram Explained [with Graphs] - Fractory 10-03-2020 · Alloy steel elements such as nickel, manganese, chromium, and molybdenum affect the position of these boundaries on the phase diagram. The boundaries may shift in either direction depending on the element used. For example, in the iron carbon phase diagram, addition of nickel lowers the A3 boundary while the addition of chromium raises it.

Metallurgy Matters: Phases, structures, and the influences ... Phase diagrams, also known as constitution diagrams or equilibrium diagrams, graphically represent the influences of alloy composition and temperature on phase changes and solidification. Figure 1 In other words, for a given alloy, the phase diagram can show the phases and percentage of each phase present at a specific temperature and alloy ...

TTT Diagram Basic - TTT diagram for steel, eutectoid steel Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.

Time Temperature Transformation (TTT) Diagrams Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath (Figs. 1-

Phase Diagram - Industrial Metallurgists 14-08-2021 · Iron-Carbon Phase Diagram An example of a commonly used phase diagram is the iron-carbon phase diagram, which is used to understand the phases present in steel. The amount of carbon present in an iron-carbon alloy, in weight percent, is plotted on the x-axis and temperature is plotted on the y-axis.

![The iron-carbon phase diagram [46]. | Download Scientific Diagram](https://www.researchgate.net/profile/Muna-Abbass/publication/293333803/figure/fig2/AS:669013386469398@1536516629671/Figure-2-11-The-iron-carbon-phase-diagram-46.png)

![Phase diagram of steel [1] (Fe-C alloy) | Download Scientific ...](https://www.researchgate.net/profile/Massimo-Zucchetti-2/publication/328770209/figure/fig15/AS:690011745820676@1541523028720/Phase-diagram-of-steel-1-Fe-C-alloy_Q640.jpg)

![Iron-Carbon Phase Diagram Explained [with Graphs]](https://fractory.com/wp-content/uploads/2020/03/Phase-diagram-of-steel-and-cast-iron.jpg)

0 Response to "40 phase diagram of steel"

Post a Comment