37 process control block diagram

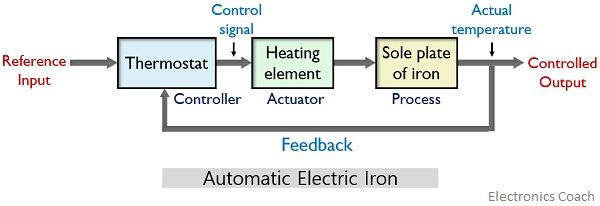

Block Diagram of a Control System. Basically block diagram of a control system pictorially represents a system. By using visual illustration, even a very complex system can be simplified for the purpose of analysis. The block diagram representation of a system is nothing but an interconnection of multiple elements of the system. Structure of the Process Control Block The process control stores many data items that are needed for efficient process management. Some of these data items are explained with the help of the given diagram − The following are the data items − Process State This specifies the process state i.e. new, ready, running, waiting or terminated.

Figure 3. Simplified PLC block diagram. A PLC is about accomplishing a task or doing a job. We first sense a physical parameter, process and decide a course of action, and command something to control a physical device. Following this model, the lower left block is the output signal conditioner which could be the MAX15500/MAX15501 integrated ...

Process control block diagram

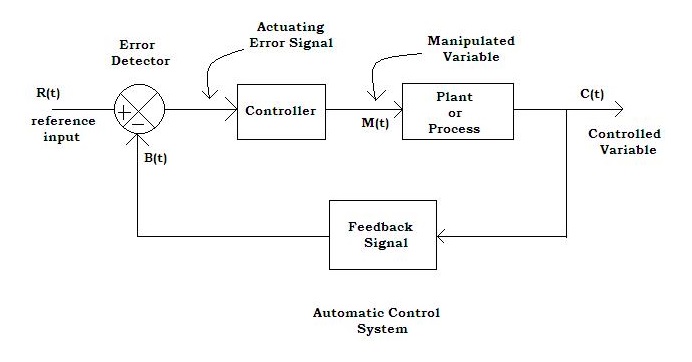

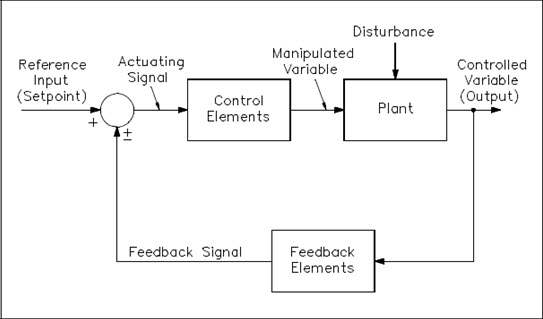

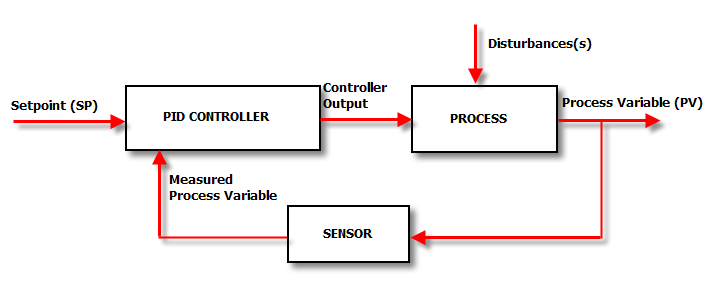

A block diagram of a simple discrete control system is shown in below figure. The devices used to sense system conditions in discrete control are typically electrical switches, with contacts that are open when the variable is in one state and closed when it is in the other. Figure : Discrete control system block diagram Apr 29, 2017 · Block diagram of process control system. Author: Technical Editor Category: Electronics Articles 29 Apr 17. The figure shows the block diagram of close loop system or process control system. The process control system consists of process or plant, feedback elements, error detector, automatic controller, actuator or control element. Block diagrams show the blocks of a control system with the interconnections that determine the direction and connections of inputs and outputs. A feedback control system consists of a sensor, actuator and controller that are connected with information flowing in a loop. The loop is created with the sensor providing information to the controller.

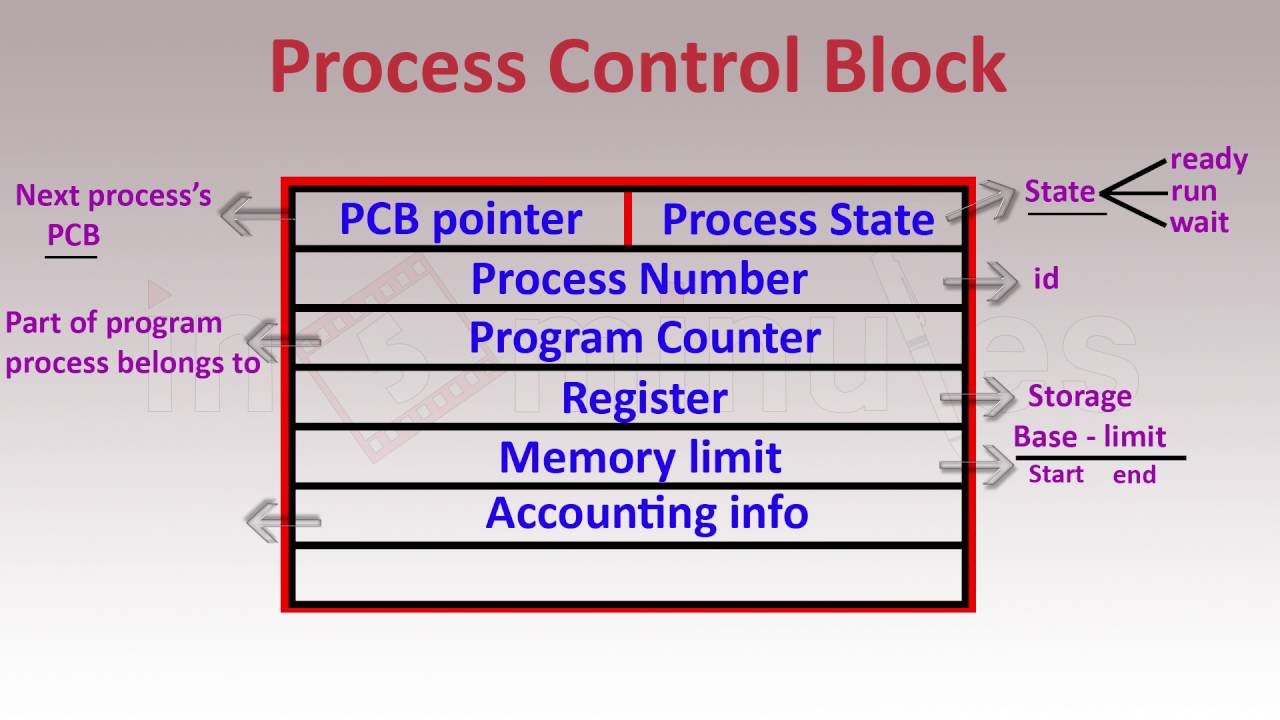

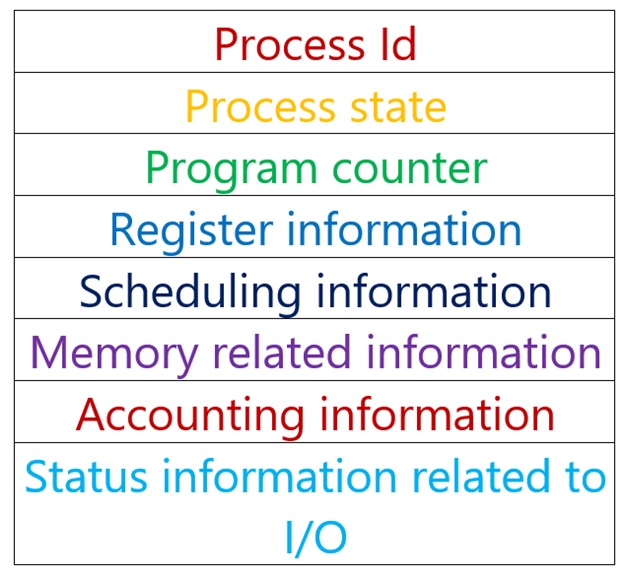

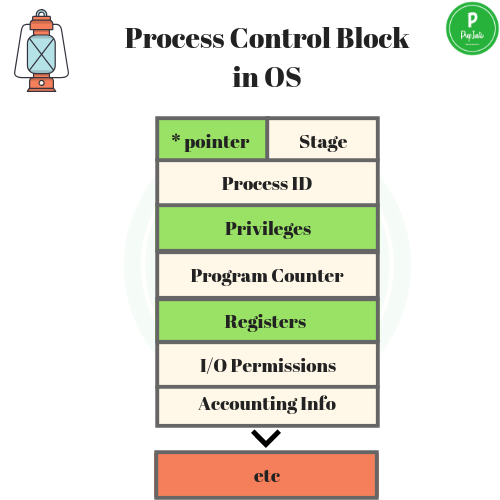

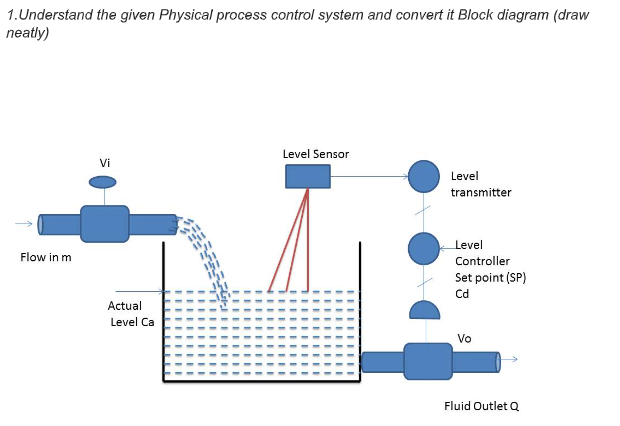

Process control block diagram. Block diagrams help us visualize the components of a loop and see how the pieces are connected. Closed Loop System Working Animation A home heating system can be a simple on/off control or a proportional control by adjusting the amount of hot fluid by throttling a control valve. Process Control Technicians are in high demand in industry. As automation continues to advance our capabilities, it also increases the difficulty of maintaining the system. Understanding the complex systems in automation begins with the basics, such as print reading. A block diagram is a pictorial representation of the cause and effect relationship between the input and output of The figures below represent industrial process and its control block diagram. Matching the components from the physical system to the block diagram. Level Control Set point (10 m) Modulating control Valve 8 USD Air Supply Water supply Capacitance probe Tank Max. What is PCB (Process Control Block)? PCB is a data structure in the OS and it contains all the information about a process. How PCB of a process is created in OS? When a process is created, the operating system creates a corresponding process control block for storing the information of that process. PCB diagram in OS

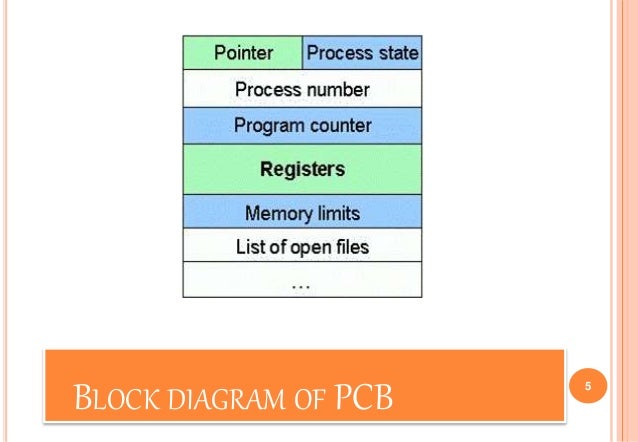

Block Diagram of Closed Loop Control System. In a closed-loop control system, a fraction of output is fed-back and added to the system's input. If H (s) is the transfer function of the feedback path, then the transfer function of the feedback signal will be B (s) = C (s)H (s). At the summing point, the input signal R (s) will be added to B (s ... Process Control block is used for storing the collection of information about the Processes and this is also called as the Data Structure which Stores the information about the process. The information of the Process is used by the CPU at the Run time. The various information which is Stored into the PCB as followings: 1) Name of the Process. Block Diagram Representation of Electrical Systems. In this section, let us represent an electrical system with a block diagram. Electrical systems contain mainly three basic elements — resistor, inductor and capacitor. Consider a series of RLC circuit as shown in the following figure. Where, V i (t) and V o (t) are the input and output voltages. Let i(t) be the current passing through the circuit. A block diagram majorly comprises rectangle shapes known as blocks and the straight lines with arrows at the end. While the blocks represent the key elements of the entire process, the arrowed lines show the relationship between the two objects and the direction the data, information, processing, signals, or the electric current flows in.

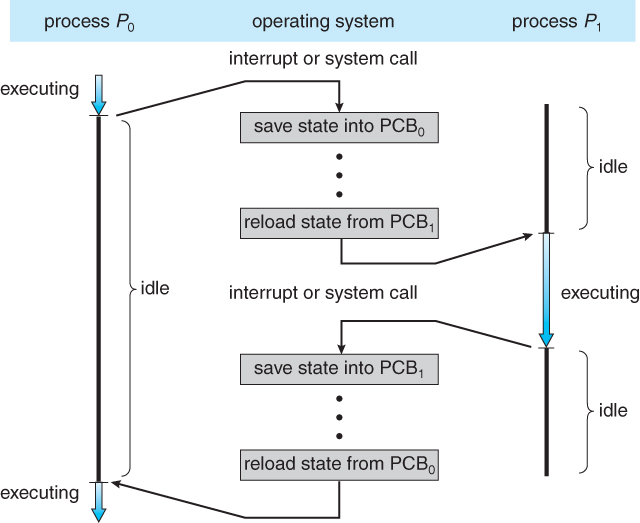

feedback control - 8.7 8.3.2 Manipulating Block Diagrams A block diagram for a system is not unique, meaning that it may be manipulated into new forms. Typically a block diagram will be developed for a system. The diagram will then be simplified through a process that is both graphical and algebraic. For exam- A process control block (PCB) contains information about the process, i.e. registers, quantum, priority, etc. The process table is an array of PCB’s, that means logically contains a PCB for all of the current processes in the system. Pointer – It is a stack pointer which is required to be saved when the process is switched from one state to ... Process Control Block Diagrams . The home heating system for this discussion uses a home furnace that can only be either ON or OFF. Develop a home heating control loop block diagram clearly showing all the key elements. Discuss the organization and operation of this home heating control loop. Process Control Block Diagram. Process control block diagram in the operating system is an important concept related to processing. In the previous process concepts tutorial, we have learned about different basics concepts of the process such as the basic introduction of process, abstract view of the process in memory or process architecture, and process state diagram.

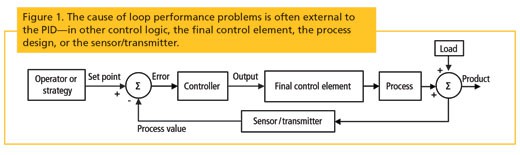

A simple control system drawn in block diagram form looks like this: Information from the measuring device (e.g. transmitter) goes to the controller, then to the final control device (e.g. control valve), influencing the process which is sensed again by the measuring device.

A process control block (PCB) is a data structure used by computer operating systems to store all the information about a process.It is also known as a process descriptor. When a process is created (initialized or installed), the operating system creates a corresponding process control block.

Mechanical Engineering questions and answers. 1) The figures below represent industrial process and its control block diagram. Matching the components from the physical system to the block diagram. Sut point (101 Modulo 20 TE W Care Warouw Min. Level Water Leaking Out Controller Actuator Plant Sensor Matching: a) Controller b) Actuator c) Plant ...

Process Control Block is a data structure that is maintained by the operating system. PCB maintains the specific information, about the process, which is helpful while its execution. As soon as the process is created it is the responsibility of the operating system to create a respective process control block for it.

Process Controls PRINCIPLES OF CONTROL SYSTEMS PRINCIPLES OF CONTROL SYSTEMS Control systems integrate elements whose function is to maintain a process variable at a desired value or within a desired range of values. EO 1.1 DEFINE the following process control terms: a. Control system b. Control system input c. Control system output d. Open ...

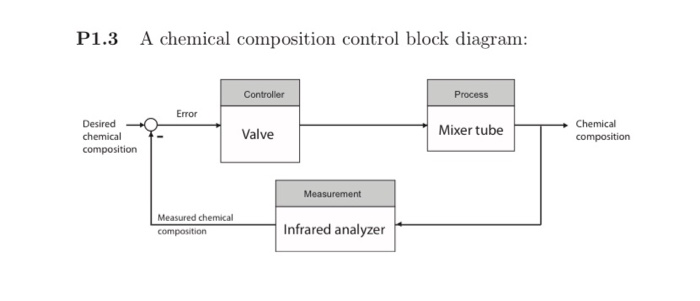

Process Control Diagrams •consider the equipment that is used to implement control strategies. •For the stirred-tank mixing system under feedback control. •the exit concentration xis controlled and the flow rate W 2 of pure species A is adjusted using proportional control. Block diagram for composition feedback control system

Dec 2, 2021 — Process Architecture; Process Control Blocks; Process States; Process Control Block (PCB) ... Here, is an Architecture diagram of the Process.

ConceptDraw flowchart maker allows you to easier create a process flowchart. Use a variety of drawing tools, smart connectors, flowchart symbols and shape libraries to create flowcharts of complex processes, process flow diagrams, procedures and information exchange. Process Control Block Diagram

A “load” is a variable influencing a process that is not itself under direct control, and may be represented in the block diagram as an arrow entering the process, but not within the control loop: For example, consider the problem of controlling the speed of an automobile.

Diagram of a Process Control Block (PCB). - a data structure used in the OS code to represent one process. - the set of PCB s is called the process table.

Block diagrams are a flow chart of signals and transfer functions that relate inputs to outputs. The dynamic response of the outputs can be simulated by piec...

Nov 09, 2016 · BLOCK DIAGRAM OF PCB 5 6. PROCESS CONTROL BLOCK (PCB) PCB consist of following information~ Pointer . Process state . Program counter . CPU register . CPU scheduling information . Memory management information . Accounting information . I/O status information . 6 7.

inlet flow is constant. Figure 2 shows the block diagram of two tanks of chemical reactor. Fig.1 The simple concentration process control Fig. 2 The block diagram of the two tank system The value of the concentration in the second tank is desired, but it depends on the concentration in the first tank. Therefore the component balances in both

Process flow diagrams of multiple process units within a large industrial plant will usually contain less detail and may be called block flow diagrams or schematic flow diagrams. Process flow diagram examples. The process flow diagram below depicts a single chemical engineering unit process known as an amine treating plant:

Block diagrams show the blocks of a control system with the interconnections that determine the direction and connections of inputs and outputs. A feedback control system consists of a sensor, actuator and controller that are connected with information flowing in a loop. The loop is created with the sensor providing information to the controller.

Apr 29, 2017 · Block diagram of process control system. Author: Technical Editor Category: Electronics Articles 29 Apr 17. The figure shows the block diagram of close loop system or process control system. The process control system consists of process or plant, feedback elements, error detector, automatic controller, actuator or control element.

A block diagram of a simple discrete control system is shown in below figure. The devices used to sense system conditions in discrete control are typically electrical switches, with contacts that are open when the variable is in one state and closed when it is in the other. Figure : Discrete control system block diagram

0 Response to "37 process control block diagram"

Post a Comment